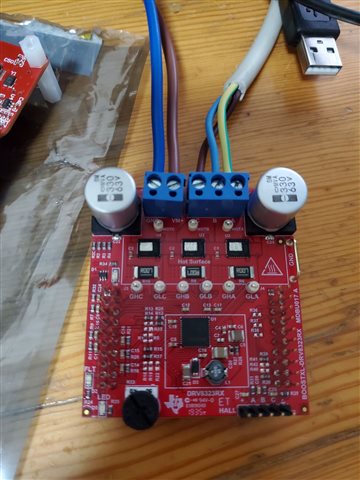

Other Parts Discussed in Thread: LAUNCHXL-F280025C, BOOSTXL-DRV8323RS

F280025C +8323RS

F280025C +8323RS

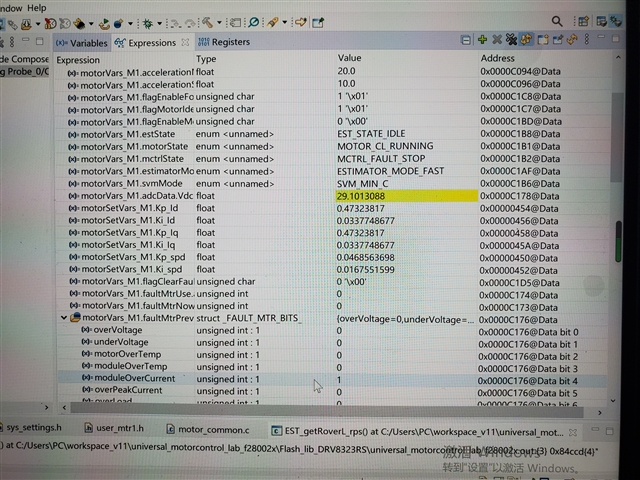

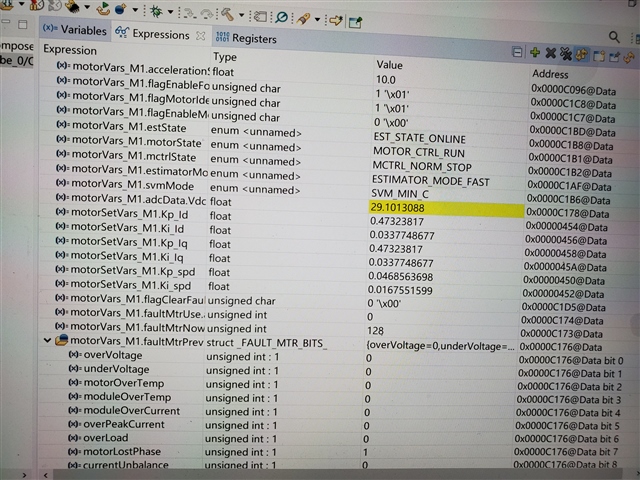

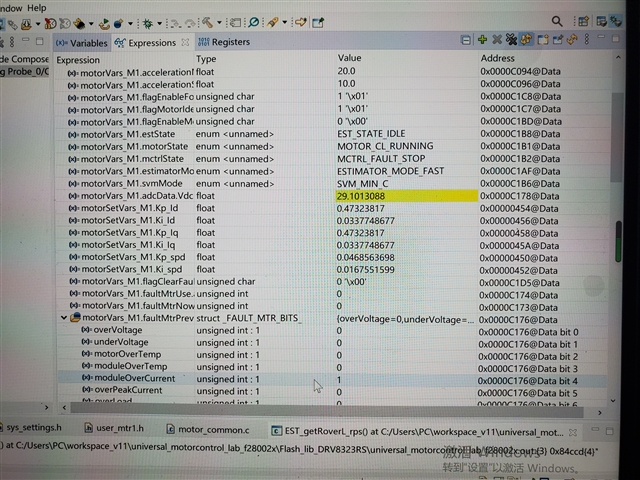

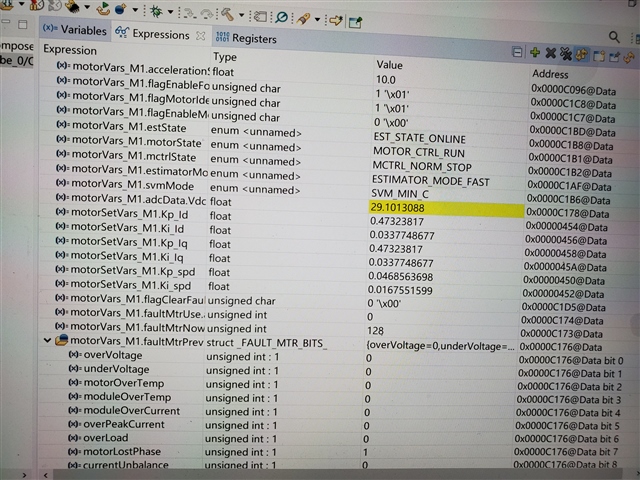

DMC_BUILDLEVEL设置为DMC_LEVEL_4来构建和加载项目 当接上电机时 出现了moduleOverCurrent = 1 和 flagEnableRunAndIdentify =0 的情况

拆除电机后 则不会出现moduleOverCurrent = 1 的情况 这个该怎么解决呢

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

F280025C +8323RS

F280025C +8323RS

DMC_BUILDLEVEL设置为DMC_LEVEL_4来构建和加载项目 当接上电机时 出现了moduleOverCurrent = 1 和 flagEnableRunAndIdentify =0 的情况

拆除电机后 则不会出现moduleOverCurrent = 1 的情况 这个该怎么解决呢

你好,我看到你有引用相同问题的帖子,帖子中FAE建议参数识别的时候不要加负载,你是否有参考?

另外,你的电机本身是运行正常的吗?

你好,这是对方回复:

Please take a look at the lab guide and follow it to connect the kits and run the lab from build level 1. Make sure that the related switches are set correctly on LAUNCHXL-F280025C, and the connection is as below shown in the lab guide. Universal Project and Lab User’s Guide: https://www.ti.com/lit/spruj26

• For more details about the BOOSTXL-DRV8323RS, see the User's Guide for the EVM.

• Make sure that the following items are completed as described below, and then connect the BOOSTXLDRV8323RS

to J1/J3 and J4/J2 of the LAUNCHXL-F280025C as shown in Figure 2-7.

– Populate C9, C10, and C11 with a 47nF capacitor.

– Bend J3-29 and J3-30 of the LAUNCHXL-F280025C90 degrees so that they are not connected to the

BOOSTXL-DRV8323RS as shown in Figure 2-5.

Please make sure that the switches are set correctly as shown in lab guide as below also, especially the S2.

是按照文档要求来的

是按照文档要求来的

moduleOverCurrent = 1 是在接上电机后才出现的,

#elif (USER_MOTOR1 == Teknic_M2310PLN04K)

#define USER_MOTOR1_TYPE MOTOR_TYPE_PM

#define USER_MOTOR1_NUM_POLE_PAIRS (4) //极对数

#define USER_MOTOR1_Rr_Ohm (NULL)

#define USER_MOTOR1_Rs_Ohm (0.38157931f) //阻值

#define USER_MOTOR1_Ls_d_H (0.000188295482f)

#define USER_MOTOR1_Ls_q_H (0.000188295482f)

#define USER_MOTOR1_RATED_FLUX_VpHz (0.0396642499f) //额定磁通VpHz

#define USER_MOTOR1_MAGNETIZING_CURRENT_A (NULL)

#define USER_MOTOR1_RES_EST_CURRENT_A (1.5f) //电机额定电流的10-30%

#define USER_MOTOR1_IND_EST_CURRENT_A (-1.5f) //电机额定电流的10-30%,足以支持旋转

#define USER_MOTOR1_MAX_CURRENT_A (2.5f) //最大电流 A 电机额定电流的50-150%

#define USER_MOTOR1_FLUX_EXC_FREQ_Hz (40.0f) //电机额定频率为10~30%

#define USER_MOTOR1_NUM_ENC_SLOTS (1000)

#define USER_MOTOR1_INERTIA_Kgm2 (7.06154e-06)

#define USER_MOTOR1_FREQ_NEARZEROLIMIT_Hz (5.0f) //频率接近零极限 Hz

#define USER_MOTOR1_RATED_VOLTAGE_V (48.0f) //额定电压

#define USER_MOTOR1_RATED_SPEED_KRPM (3.0f) //额定速度KRPM

#define USER_MOTOR1_FREQ_MIN_HZ (9.0f) //频率最小赫兹 Hz

#define USER_MOTOR1_FREQ_MAX_HZ (600.0f) //频率最大 Hz

#define USER_MOTOR1_FREQ_LOW_HZ (5.0f) //频率低 Hz

#define USER_MOTOR1_FREQ_HIGH_HZ (800.0f) //频率高 Hz

#define USER_MOTOR1_VOLT_MIN_V (12.0f) //电压最小值 Volt

#define USER_MOTOR1_VOLT_MAX_V (50.0f) //电压最大值 Volt

#define USER_MOTOR1_FORCE_DELTA_A (0.05f) //力增量 A

#define USER_MOTOR1_ALIGN_DELTA_A (0.01f) //对齐增量 A

#define USER_MOTOR1_FLUX_CURRENT_A (0.5f) //磁通电流 A

#define USER_MOTOR1_ALIGN_CURRENT_A (1.5f) //对齐电流 A

#define USER_MOTOR1_STARTUP_CURRENT_A (2.5f) //启动电流 A 电机额定电流的30-100%

#define USER_MOTOR1_TORQUE_CURRENT_A (2.0f) //转矩电流 A

#define USER_MOTOR1_OVER_CURRENT_A (2.8f) // 过电流 A 电机额定电流的50-150 %

#define USER_MOTOR1_BRAKE_CURRENT_A (1.0f) //制动器电流 A

#define USER_MOTOR1_BRAKE_TIME_DELAY (12000U) //制动延时 60s/5ms

问题究竟出在哪里?

你好,你的build level还是4吗?有没有改成1之后再测试一下?

另外,可以尝试修改以下参数,把数值慢慢增大看是否有效:

#define USER_MOTOR1_MAX_CURRENT_A (2.5f)

#define USER_MOTOR1_OVER_CURRENT_A (2.8f)

你好,针对你之前回复的,LEVEL 1正常,LEVEL 4异常的情况,这边工程师的建议是按照lab指南从 2 级运行到 4 级,这个过程中进行识别或设置正确的电机参数直到在 4 级运行电机。

关于你最新回复的我会再去咨询一下。

这个E2E帖子是我升级的问题,回复问题的Yanming Luo是电机控制方面的专家,目前对方没有提及关于“问题在哪里”的回复,你可以追问一下。

e2e.ti.com/.../tms320f280025c-moduleovercurrent-1-flagenablerunandidentify-0