Other Parts Discussed in Thread: TMDSCNCD280039C, TMDSHSECDOCK, , PMP22650

Hi,

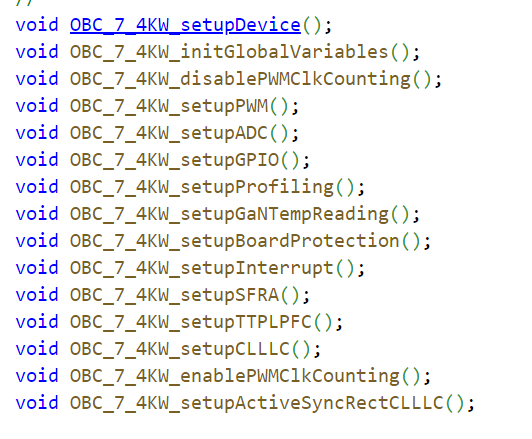

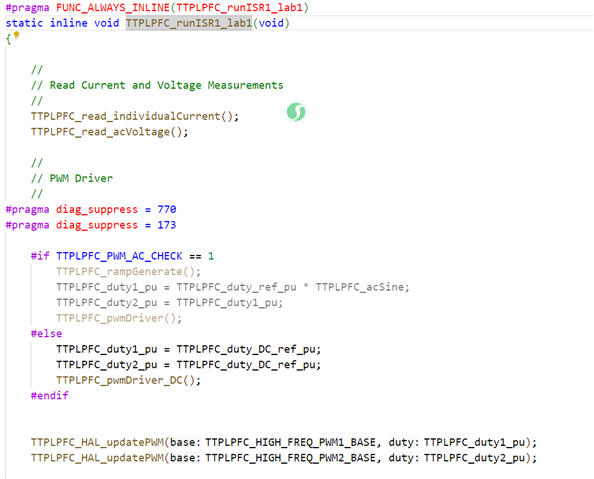

My team and I are replicating this circuit board.

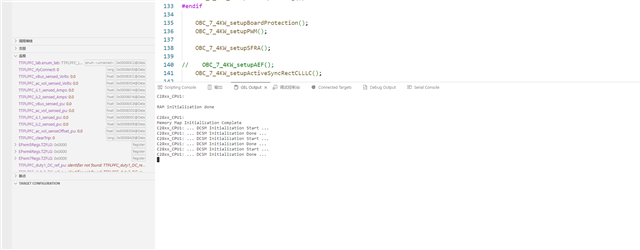

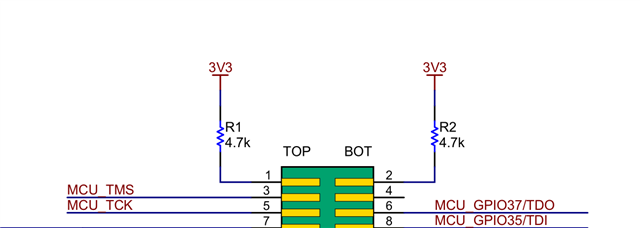

When I was not connected to an auxiliary power source (12v 2A), JTAG is normal.

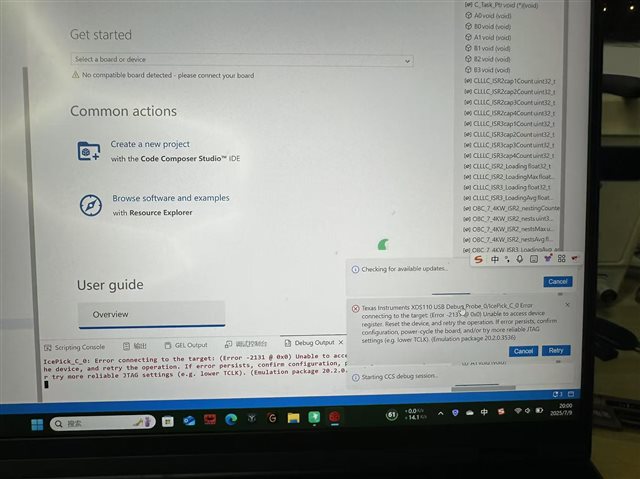

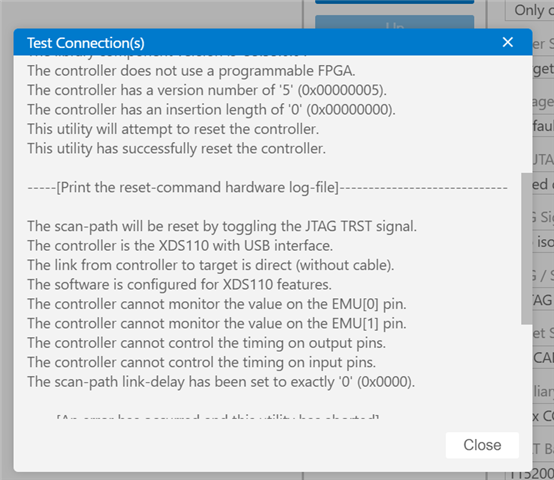

But when I connected the auxiliary power supply,JTAG will cease.

Could you please tell me the solution?