Other Parts Discussed in Thread: C2000WARE, , LAUNCHXL-F2800137

开发一款电调,MCU:TMS320F2800137,SDK:C:\ti\c2000\C2000Ware_MotorControl_SDK_4_02_01_00\solutions\universal_motorcontrol_lab\f280013x,问题如下:

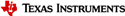

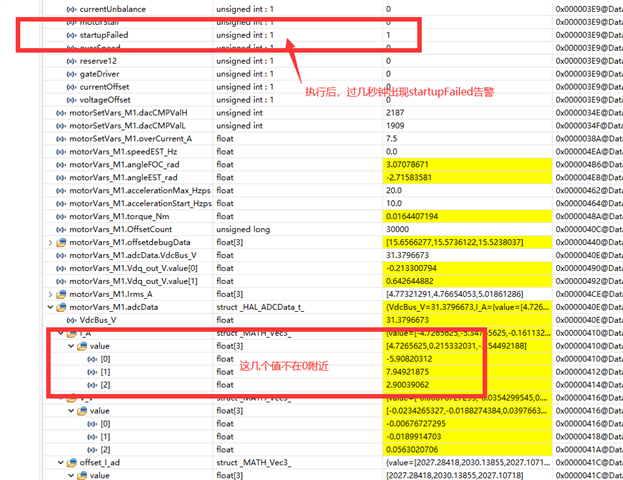

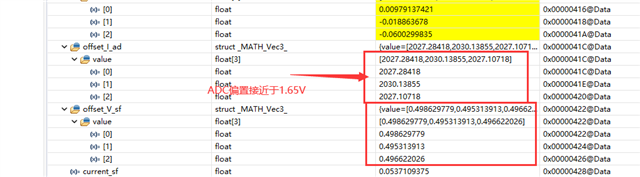

1、根据开发文档,#define DMC_BUILDLEVEL DMC_LEVEL_1,offset_v_sf偏移值应该在0.5上下,而我的自己的样板的值始终在0.14上下;

2、对比TI的官方LAUNCHXL-F2800137开发板+8353RX-EVM,offset_v_sf偏移值应该在0.5上下;

3、仔细分析代码,偏移计算在motor1_driver.c中runMotor1OffsetsCalculation()中做了如下30000次计算:

// clear the ADC interrupt flag

ADC_clearInterruptStatus(MTR1_ADC_INT_BASE, MTR1_ADC_INT_NUM);

while(ADC_getInterruptStatus(MTR1_ADC_INT_BASE, MTR1_ADC_INT_NUM) == false);

HAL_readMtr1ADCData(&obj->adcData);

if(offsetCnt >= 2000) // Ignore the first 2000 times

{

obj->OffsetCount = offsetCnt - 1999; //lzx add for counter offset calculation;

obj->offsetdebugData[0] = obj->adcData.offset_V_sf.value[0];

obj->offsetdebugData[1] = obj->adcData.offset_V_sf.value[1];

obj->offsetdebugData[2] = obj->adcData.offset_V_sf.value[2];

// Offsets in phase current sensing

#if defined(MOTOR1_ISBLDC)

obj->adcData.offset_Idc_ad = offsetK1 * obj->adcData.offset_Idc_ad +

(obj->adcData.Idc1_A.value[0] + obj->adcData.Idc1_A.value[1]) * 0.5f * offsetK2;

#elif defined(MOTOR1_DCLINKSS)

obj->adcData.offset_Idc_ad = offsetK1 * obj->adcData.offset_Idc_ad +

0.25f * offsetK2 *(obj->adcData.Idc1_A.value[0] +

obj->adcData.Idc1_A.value[1] +

obj->adcData.Idc2_A.value[0] +

obj->adcData.Idc2_A.value[1]);

#else // !(MOTOR1_ISBLDC || MOTOR1_DCLINKSS)

obj->adcData.offset_I_ad.value[0] =

offsetK1 * obj->adcData.offset_I_ad.value[0] +

obj->adcData.I_A.value[0] * offsetK2;

obj->adcData.offset_I_ad.value[1] =

offsetK1 * obj->adcData.offset_I_ad.value[1] +

obj->adcData.I_A.value[1] * offsetK2;

obj->adcData.offset_I_ad.value[2] =

offsetK1 * obj->adcData.offset_I_ad.value[2] +

obj->adcData.I_A.value[2] * offsetK2;

#endif // !(MOTOR1_ISBLDC || MOTOR1_DCLINKSS)

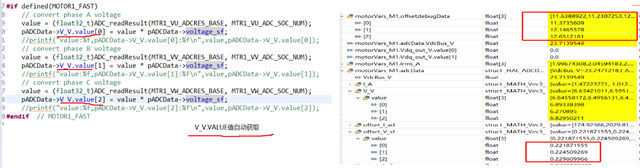

#if defined(MOTOR1_FAST) || defined(MOTOR1_ISBLDC)

//obj->adcData.VdcBus_V = 0.0324213766f;

invVdcbus = 1.0f / obj->adcData.VdcBus_V;

//if(offsetCnt < 2100)

//printf("obj->adcData.offset_V_sf.value[0]:%f,obj->adcData.V_V.value[0]:%f\n",obj->adcData.offset_V_sf.value[0],obj->adcData.V_V.value[0]);

// Offsets in phase voltage sensing

obj->adcData.offset_V_sf.value[0] =

offsetK1 * obj->adcData.offset_V_sf.value[0] +

(invVdcbus * obj->adcData.V_V.value[0]) * offsetK2;

obj->adcData.offset_V_sf.value[1] =

offsetK1 * obj->adcData.offset_V_sf.value[1] +

(invVdcbus * obj->adcData.V_V.value[1]) * offsetK2;

obj->adcData.offset_V_sf.value[2] =

offsetK1 * obj->adcData.offset_V_sf.value[2] +

(invVdcbus * obj->adcData.V_V.value[2]) * offsetK2;

#endif // MOTOR1_FAST || MOTOR1_ISBLDC

}

else if(offsetCnt <= 1000)

{

// enable the PWM

HAL_enablePWM(obj->halMtrHandle);

}

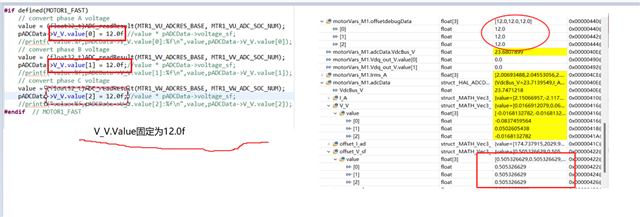

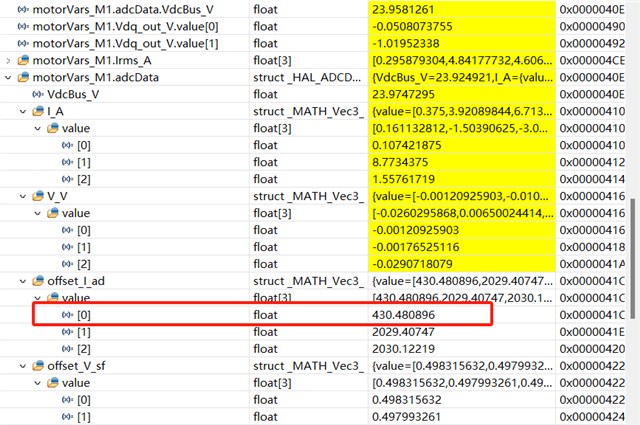

实际参与计算的参数有offsetK1 ,offsetK2,adcData.V_V.value,invVdcbus ,为什么我的板子就算出来的参数越来越小,30000次计算后再0.14上下?

请贵司帮忙分析我的板子电压偏移计算为什么越来越小,而TI的官方LAUNCHXL-F2800137开发板+8353RX-EVM计算值始终保持在0.5上下?

偏移值计算主要和哪些参数有关?