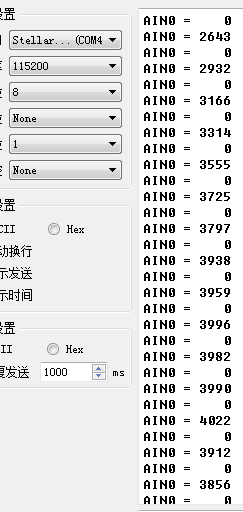

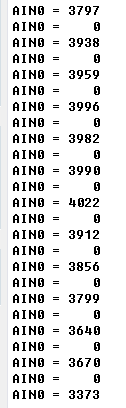

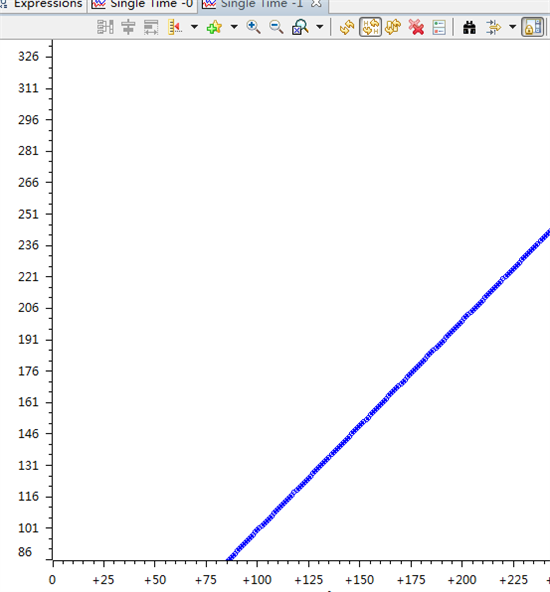

配置ADC0 四通道采样,软件触发,为什么每次采回的数据顺序都不一样,是跟溢出有关吗,请问怎样解决。测试代码如下:

#define ADC_Sequencer 1

#define ADC_BASE ADC0_BASE

void main(void) {

SysCtlClockSet(SYSCTL_SYSDIV_4|SYSCTL_USE_PLL|SYSCTL_XTAL_16MHZ|

SYSCTL_OSC_MAIN);

SystemClock=SysCtlClockGet();

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0);

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOD);

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE);

MAP_GPIOPinTypeADC(GPIO_PORTD_BASE, GPIO_PIN_1);

MAP_GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_2);

MAP_GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_1);

MAP_GPIOPinTypeADC(GPIO_PORTD_BASE, GPIO_PIN_2);

ADCSequenceConfigure(ADC_BASE, ADC_Sequencer, ADC_TRIGGER_PROCESSOR, 0);

ADCHardwareOversampleConfigure(ADC_BASE,8);

ADCSequenceStepConfigure(ADC_BASE, ADC_Sequencer, 0,

ADC_CTL_CH1);

ADCSequenceStepConfigure(ADC_BASE, ADC_Sequencer, 1,

ADC_CTL_CH2);

ADCSequenceStepConfigure(ADC_BASE, ADC_Sequencer, 2,

ADC_CTL_CH4);

ADCSequenceStepConfigure(ADC_BASE, ADC_Sequencer, 3,

ADC_CTL_IE | ADC_CTL_END | ADC_CTL_CH5);

ADCSequenceEnable(ADC_BASE, ADC_Sequencer);

ADCIntClear(ADC0_BASE, ADC_Sequencer);

ADCIntRegister(ADC0_BASE,ADC_Sequencer,ADC1IntHandler);

ADCIntEnable(ADC0_BASE,ADC_Sequencer);

IntMasterEnable();

while(1)

{

ADCProcessorTrigger(ADC_BASE, ADC_Sequencer);

SysCtlDelay(5000);

_nop();

}

}

void ADC1IntHandler()

{

ADCIntClear(ADC0_BASE, ADC_Sequencer);

ADCSequenceDataGet(ADC0_BASE, ADC_Sequencer, AD0IN4);

_nop();

}