主题中讨论的其他器件: BOOSTXL-DRV8305EVM

你(们)好

我们使用 LaunchXL-F28027F+ BoostxL-DRV8305EVM 演示板 来驱动24V BLDC。 电机的实际参数为 :定子电阻0.15欧姆、 定子电感13.5uH、 磁通0.00831 V/Hz。电机需要在低速轻负载、低速重负载(300rpm)和高速轻负载(40000rpm)三种工作条件下稳定运行。

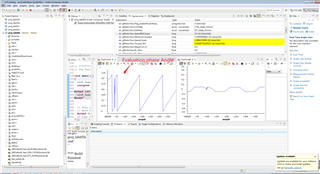

遗憾的是、使用例程 proj_lab2b 来识别电机参数(电阻和磁通 估算 准确)时、定子电感识别的估算不准确、并且 在 use.h 文件中使用的实际电机参数情况下、速度闭环运行不稳定—— 在整个负载范围内(仅300rpm)难以应用相同的 Kp、Ki 值。

我的所有问题都来自猜测电机运行不稳定的原因(使用例程 proj_lab5b):

1.估算的转子相位角偶尔跳转是否正常? 是否是电机运行不稳定的原因?

2. "偶尔跳转的估算转子相位角"和"定子电感识别的估算不准确"是否 与内在相关?

3. 问题与错误的 KpKi 值有关? 建议的 KpKi 值似乎不适合不同的负载情况。

期待您的帮助、谢谢!

#ifndef _USER_H_

#define _USER_H_

/* --COPYRIGHT--,BSD

* Copyright (c) 2015, Texas Instruments Incorporated

* All rights reserved.

*

* Redistribution and use in source and binary forms, with or without

* modification, are permitted provided that the following conditions

* are met:

*

* * Redistributions of source code must retain the above copyright

* notice, this list of conditions and the following disclaimer.

*

* * Redistributions in binary form must reproduce the above copyright

* notice, this list of conditions and the following disclaimer in the

* documentation and/or other materials provided with the distribution.

*

* * Neither the name of Texas Instruments Incorporated nor the names of

* its contributors may be used to endorse or promote products derived

* from this software without specific prior written permission.

*

* THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS"

* AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

* THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

* PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR

* CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

* EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

* PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS;

* OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

* WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR

* OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE,

* EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

* --/COPYRIGHT--*/

//! \file solutions/instaspin_foc/boards/boostxl-drv8305evm_revA/f28x/f2802xF/src/user.h

//! \brief Contains the public interface for user initialization data for the CTRL, HAL, and EST modules

//!

//! (C) Copyright 2015, Texas Instruments, Inc.

// **************************************************************************

// the includes

// modules

#include "sw/modules/types/src/types.h"

#include "sw/modules/motor/src/32b/motor.h"

#include "sw/modules/est/src/32b/est.h"

#include "sw/modules/est/src/est_states.h"

#include "sw/modules/est/src/est_Flux_states.h"

#include "sw/modules/est/src/est_Ls_states.h"

#include "sw/modules/est/src/est_Rs_states.h"

#include "sw/modules/ctrl/src/32b/ctrl_obj.h"

// platforms

#include "sw/modules/fast/src/32b/userParams.h"

//!

//!

//! \defgroup USER USER

//!

//@{

#ifdef __cplusplus

extern "C" {

#endif

// **************************************************************************

// the defines

//! \brief CURRENTS AND VOLTAGES

// **************************************************************************

//! \brief Defines the full scale frequency for IQ variable, Hz

//! \brief All frequencies are converted into (pu) based on the ratio to this value

//! \brief this value MUST be larger than the maximum speed that you are expecting from the motor

#define USER_IQ_FULL_SCALE_FREQ_Hz (1360.0) // 800 Example with buffer for 8-pole 6 KRPM motor to be run to 10 KRPM with field weakening; Hz =(RPM * Poles) / 120

//! \brief Defines full scale value for the IQ30 variable of Voltage inside the system

//! \brief All voltages are converted into (pu) based on the ratio to this value

//! \brief WARNING: this value MUST meet the following condition: USER_IQ_FULL_SCALE_VOLTAGE_V > 0.5 * USER_MOTOR_MAX_CURRENT * USER_MOTOR_Ls_d * USER_VOLTAGE_FILTER_POLE_rps,

//! \brief WARNING: otherwise the value can saturate and roll-over, causing an inaccurate value

//! \brief WARNING: this value is OFTEN greater than the maximum measured ADC value, especially with high Bemf motors operating at higher than rated speeds

//! \brief WARNING: if you know the value of your Bemf constant, and you know you are operating at a multiple speed due to field weakening, be sure to set this value higher than the expected Bemf voltage

//! \brief It is recommended to start with a value ~3x greater than the USER_ADC_FULL_SCALE_VOLTAGE_V and increase to 4-5x if scenarios where a Bemf calculation may exceed these limits

//! \brief This value is also used to calculate the minimum flux value: USER_IQ_FULL_SCALE_VOLTAGE_V/USER_EST_FREQ_Hz/0.7

#define USER_IQ_FULL_SCALE_VOLTAGE_V (32.0) // 24.0 Set to Vbus

//! \brief Defines the maximum voltage at the input to the AD converter

//! \brief The value that will be represented by the maximum ADC input (3.3V) and conversion (0FFFh)

//! \brief Hardware dependent, this should be based on the voltage sensing and scaling to the ADC input

#define USER_ADC_FULL_SCALE_VOLTAGE_V (44.30) // BOOSTXL-DRV8305EVM = 44.30 V

//! \brief Defines the voltage scale factor for the system

//! \brief Compile time calculation for scale factor (ratio) used throughout the system

#define USER_VOLTAGE_SF ((float_t)((USER_ADC_FULL_SCALE_VOLTAGE_V)/(USER_IQ_FULL_SCALE_VOLTAGE_V)))

//! \brief Defines the full scale current for the IQ variables, A

//! \brief All currents are converted into (pu) based on the ratio to this value

//! \brief WARNING: this value MUST be larger than the maximum current readings that you are expecting from the motor or the reading will roll over to 0, creating a control issue

#define USER_IQ_FULL_SCALE_CURRENT_A (24.0) // BOOSTXL-DRV8305EVM = 24.0 A

//! \brief Defines the maximum current at the AD converter

//! \brief The value that will be represented by the maximum ADC input (3.3V) and conversion (0FFFh)

//! \brief Hardware dependent, this should be based on the current sensing and scaling to the ADC input

#define USER_ADC_FULL_SCALE_CURRENT_A (47.14) // BOOSTXL-DRV8305EVM = 47.14 A

//! \brief Defines the current scale factor for the system

//! \brief Compile time calculation for scale factor (ratio) used throughout the system

#define USER_CURRENT_SF ((float_t)((USER_ADC_FULL_SCALE_CURRENT_A)/(USER_IQ_FULL_SCALE_CURRENT_A)))

//! \brief Defines the number of current sensors used

//! \brief Defined by the hardware capability present

//! \brief May be (2) or (3)

#define USER_NUM_CURRENT_SENSORS (3) // 3 Preferred setting for best performance across full speed range, allows for 100% duty cycle

//! \brief Defines the number of voltage (phase) sensors

//! \brief Must be (3)

#define USER_NUM_VOLTAGE_SENSORS (3) // 3 Required

//! \brief ADC current offsets for A, B, and C phases

//! \brief One-time hardware dependent, though the calibration can be done at run-time as well

//! \brief After initial board calibration these values should be updated for your specific hardware so they are available after compile in the binary to be loaded to the controller

#define I_A_offset (1.018392086) // 0.5*USER_CURRENT_SF

#define I_B_offset (1.012971282) // BOOSTXL-DRV8305EVM = 1.044038892 原(1.209441483)

#define I_C_offset (1.007300496) // BOOSTXL-DRV8305EVM = 1.040363491 原(1.209092796)

//! \brief ADC voltage offsets for A, B, and C phases

//! \brief One-time hardware dependent, though the calibration can be done at run-time as well

//! \brief After initial board calibration these values should be updated for your specific hardware so they are available after compile in the binary to be loaded to the controller

#define V_A_offset (0.3791541457) //理想值:(Vbus/2/USER_ADC_FULL_SCALE_VOLTAGE_V)*USER_VOLTAGE_SF

#define V_B_offset (0.3779945374) // BOOSTXL-DRV8305EVM = 0.5250559449 (0.5074239969)

#define V_C_offset (0.3747828007) // BOOSTXL-DRV8305EVM = 0.5247237682 (0.5065535307)

//! \brief CLOCKS & TIMERS

// **************************************************************************

//! \brief Defines the system clock frequency, MHz

#define USER_SYSTEM_FREQ_MHz (60.0)

//! \brief Defines the Pulse Width Modulation (PWM) frequency, kHz

//! \brief PWM frequency can be set directly here up to 30 KHz safely (60 KHz MAX in some cases)

//! \brief For higher PWM frequencies (60 KHz+ typical for low inductance, high current ripple motors) it is recommended to use the ePWM hardware

//! \brief and adjustable ADC SOC to decimate the ADC conversion done interrupt to the control system, or to use the software Que example.

//! \brief Otherwise you risk missing interrupts and disrupting the timing of the control state machine

#define USER_PWM_FREQ_kHz (45.0) //30.0 Example, 8.0 - 30.0 KHz typical; 45-80 KHz may be required for very low inductance, high speed motors

//! \brief Defines the maximum Voltage vector (Vs) magnitude allowed. This value sets the maximum magnitude for the output of the

//! \brief Id and Iq PI current controllers. The Id and Iq current controller outputs are Vd and Vq.

//! \brief The relationship between Vs, Vd, and Vq is: Vs = sqrt(Vd^2 + Vq^2). In this FOC controller, the

//! \brief Vd value is set equal to USER_MAX_VS_MAG*USER_VD_MAG_FACTOR. Vq = sqrt(USER_MAX_VS_MAG^2 - Vd^2).

//! \brief Set USER_MAX_VS_MAG = 0.5 for a pure sinewave with a peak at SQRT(3)/2 = 86.6% duty cycle. No current reconstruction is needed for this scenario.

//! \brief Set USER_MAX_VS_MAG = 1/SQRT(3) = 0.5774 for a pure sinewave with a peak at 100% duty cycle. Current reconstruction will be needed for this scenario (Lab10a-x).

//! \brief Set USER_MAX_VS_MAG = 2/3 = 0.6666 to create a trapezoidal voltage waveform. Current reconstruction will be needed for this scenario (Lab10a-x).

//! \brief For space vector over-modulation, see lab 10 for details on system requirements that will allow the SVM generator to go all the way to trapezoidal.

#define USER_MAX_VS_MAG_PU (0.5) // Set to 0.5 if a current reconstruction technique is not used. Look at the module svgen_current in lab10a-x for more info.

//! \brief Defines the address of estimator handle

//!

#define USER_EST_HANDLE_ADDRESS (0x600)

//! \brief Defines the direct voltage (Vd) scale factor

//!

#define USER_VD_SF (0.95)

//! \brief Defines the Pulse Width Modulation (PWM) period, usec

//! \brief Compile time calculation

#define USER_PWM_PERIOD_usec (1000.0/USER_PWM_FREQ_kHz)

//! \brief Defines the Interrupt Service Routine (ISR) frequency, Hz

//!

#define USER_ISR_FREQ_Hz ((float_t)USER_PWM_FREQ_kHz * 1000.0 / (float_t)USER_NUM_PWM_TICKS_PER_ISR_TICK)

//! \brief Defines the Interrupt Service Routine (ISR) period, usec

//!

#define USER_ISR_PERIOD_usec (USER_PWM_PERIOD_usec * (float_t)USER_NUM_PWM_TICKS_PER_ISR_TICK)

//! \brief DECIMATION

// **************************************************************************

//! \brief Defines the number of pwm clock ticks per isr clock tick

//! Note: Valid values are 1, 2 or 3 only

#define USER_NUM_PWM_TICKS_PER_ISR_TICK (3)

//! \brief Defines the number of isr ticks (hardware) per controller clock tick (software)

//! \brief Controller clock tick (CTRL) is the main clock used for all timing in the software

//! \brief Typically the PWM Frequency triggers (can be decimated by the ePWM hardware for less overhead) an ADC SOC

//! \brief ADC SOC triggers an ADC Conversion Done

//! \brief ADC Conversion Done triggers ISR

//! \brief This relates the hardware ISR rate to the software controller rate

//! \brief Typcially want to consider some form of decimation (ePWM hardware, CURRENT or EST) over 16KHz ISR to insure interrupt completes and leaves time for background tasks

#define USER_NUM_ISR_TICKS_PER_CTRL_TICK (1) // 2 Example, controller clock rate (CTRL) runs at PWM / 2; ex 30 KHz PWM, 15 KHz control

//! \brief Defines the number of controller clock ticks per current controller clock tick

//! \brief Relationship of controller clock rate to current controller (FOC) rate

#define USER_NUM_CTRL_TICKS_PER_CURRENT_TICK (1) // 1 Typical, Forward FOC current controller (Iq/Id/IPARK/SVPWM) runs at same rate as CTRL.

//! \brief Defines the number of controller clock ticks per estimator clock tick

//! \brief Relationship of controller clock rate to estimator (FAST) rate

//! \brief Depends on needed dynamic performance, FAST provides very good results as low as 1 KHz while more dynamic or high speed applications may require up to 15 KHz

#define USER_NUM_CTRL_TICKS_PER_EST_TICK (1) // 1 Typical, FAST estimator runs at same rate as CTRL;

//! \brief Defines the number of controller clock ticks per speed controller clock tick

//! \brief Relationship of controller clock rate to speed loop rate

#define USER_NUM_CTRL_TICKS_PER_SPEED_TICK (15) // 15 Typical to match PWM, ex: 15KHz PWM, controller, and current loop, 1KHz speed loop

//! \brief Defines the number of controller clock ticks per trajectory clock tick

//! \brief Relationship of controller clock rate to trajectory loop rate

//! \brief Typically the same as the speed rate

#define USER_NUM_CTRL_TICKS_PER_TRAJ_TICK (15) // 15 Typical to match PWM, ex: 10KHz controller & current loop, 1KHz speed loop, 1 KHz Trajectory

//! \brief Defines the controller frequency, Hz

//! \brief Compile time calculation

#define USER_CTRL_FREQ_Hz (uint_least32_t)(USER_ISR_FREQ_Hz/USER_NUM_ISR_TICKS_PER_CTRL_TICK)

//! \brief Defines the estimator frequency, Hz

//! \brief Compile time calculation

#define USER_EST_FREQ_Hz (uint_least32_t)(USER_CTRL_FREQ_Hz/USER_NUM_CTRL_TICKS_PER_EST_TICK)

//! \brief Defines the trajectory frequency, Hz

//! \brief Compile time calculation

#define USER_TRAJ_FREQ_Hz (uint_least32_t)(USER_CTRL_FREQ_Hz/USER_NUM_CTRL_TICKS_PER_TRAJ_TICK)

//! \brief Defines the controller execution period, usec

//! \brief Compile time calculation

#define USER_CTRL_PERIOD_usec (USER_ISR_PERIOD_usec * USER_NUM_ISR_TICKS_PER_CTRL_TICK)

//! \brief Defines the controller execution period, sec

//! \brief Compile time calculation

#define USER_CTRL_PERIOD_sec ((float_t)USER_CTRL_PERIOD_usec/(float_t)1000000.0)

//! \brief LIMITS

// **************************************************************************

//! \brief Defines the maximum negative current to be applied in Id reference

//! \brief Used in field weakening only, this is a safety setting (e.g. to protect against demagnetization)

//! \brief User must also be aware that overall current magnitude [sqrt(Id^2 + Iq^2)] should be kept below any machine design specifications

#define USER_MAX_NEGATIVE_ID_REF_CURRENT_A (-0.5 * USER_MOTOR_MAX_CURRENT) // -0.5 * USER_MOTOR_MAX_CURRENT Example, adjust to meet safety needs of your motor

//! \brief Defines the low speed limit for the flux integrator, p

//! \brief This is the speed range (CW/CCW) at which the ForceAngle object is active, but only if Enabled

//! \brief Outside of this speed - or if Disabled - the ForcAngle will NEVER be active and the angle is provided by FAST only

#define USER_ZEROSPEEDLIMIT (0.5 / USER_IQ_FULL_SCALE_FREQ_Hz) // 0.002 pu, 1-5 Hz typical; Hz = USER_ZEROSPEEDLIMIT * USER_IQ_FULL_SCALE_FREQ_Hz

//! \brief Defines the force angle frequency,

//! \brief Frequency of stator vector rotation used by the ForceAngle object

//! \brief Can be positive or negative

#define USER_FORCE_ANGLE_FREQ_Hz (2.0 * USER_ZEROSPEEDLIMIT * USER_IQ_FULL_SCALE_FREQ_Hz) // Default will keep FREQ >= 2.0 * low speed limit for the flux integrator

//! \brief Defines the maximum current slope for Id trajectory during PowerWarp

//! \brief For Induction motors only, controls how fast Id input can change under PowerWarp control

#define USER_MAX_CURRENT_SLOPE_POWERWARP (0.3*USER_MOTOR_RES_EST_CURRENT/USER_IQ_FULL_SCALE_CURRENT_A/USER_TRAJ_FREQ_Hz) // 0.3*RES_EST_CURRENT / IQ_FULL_SCALE_CURRENT / TRAJ_FREQ Typical to produce 1-sec rampup/down

//! \brief Defines the starting maximum acceleration AND deceleration for the speed profiles, Hz/s

//! \brief Updated in run-time through user functions

//! \brief Inverter, motor, inertia, and load will limit actual acceleration capability

#define USER_MAX_ACCEL_Hzps (20.0) // 20.0 Default

//! \brief Defines maximum acceleration for the estimation speed profiles, Hz/s

//! \brief Only used during Motor ID (commission)

#define USER_MAX_ACCEL_EST_Hzps (5.0) // 5.0 Default, don't change

//! \brief Defines the maximum current slope for Id trajectory during estimation

#define USER_MAX_CURRENT_SLOPE (USER_MOTOR_RES_EST_CURRENT/USER_IQ_FULL_SCALE_CURRENT_A/USER_TRAJ_FREQ_Hz) // USER_MOTOR_RES_EST_CURRENT/USER_IQ_FULL_SCALE_CURRENT_A/USER_TRAJ_FREQ_Hz Default, don't change

//! \brief Defines the fraction of IdRated to use during rated flux estimation

//!

#define USER_IDRATED_FRACTION_FOR_RATED_FLUX (1.0) // 1.0 Default, don't change

//! \brief Defines the fraction of IdRated to use during inductance estimation

//!

#define USER_IDRATED_FRACTION_FOR_L_IDENT (1.0) // 1.0 Default, don't change

//! \brief Defines the IdRated delta to use during estimation

//!

#define USER_IDRATED_DELTA (0.00002)

//! \brief Defines the fraction of SpeedMax to use during inductance estimation

//!

#define USER_SPEEDMAX_FRACTION_FOR_L_IDENT (1.0) // 1.0 Default, don't change

//! \brief Defines flux fraction to use during inductance identification

//!

#define USER_FLUX_FRACTION (1.0) // 1.0 Default, don't change

//! \brief Defines the PowerWarp gain for computing Id reference

//! \brief Induction motors only

#define USER_POWERWARP_GAIN (1.0) // 1.0 Default, don't change

//! \brief Defines the R/L estimation frequency, Hz

//! \brief User higher values for low inductance motors and lower values for higher inductance

//! \brief motors. The values can range from 100 to 300 Hz.

#define USER_R_OVER_L_EST_FREQ_Hz (300) // 300 Default for high speed motors, can reduce to 100 if RoverL from Motor ID is < 2000

//! \brief POLES

// **************************************************************************

//! \brief Defines the analog voltage filter pole location, Hz

//! \brief Must match the hardware filter for Vph

#define USER_VOLTAGE_FILTER_POLE_Hz (344.62) // BOOSTXL-DRV8305 = 344.62 Hz

//! \brief Defines the analog voltage filter pole location, rad/s

//! \brief Compile time calculation from Hz to rad/s

#define USER_VOLTAGE_FILTER_POLE_rps (2.0 * MATH_PI * USER_VOLTAGE_FILTER_POLE_Hz)

//! \brief Defines the software pole location for the voltage and current offset estimation, rad/s

//! \brief Should not be changed from default of (20.0)

#define USER_OFFSET_POLE_rps (20.0) // 20.0 Default, do not change

//! \brief Defines the software pole location for the flux estimation, rad/s

//! \brief Should not be changed from default of (100.0)

#define USER_FLUX_POLE_rps (100.0) // 100.0 Default, do not change

//! \brief Defines the software pole location for the direction filter, rad/s

#define USER_DIRECTION_POLE_rps (6.0) // 6.0 Default, do not change

//! \brief Defines the software pole location for the speed control filter, rad/s

#define USER_SPEED_POLE_rps (100.0) // 100.0 Default, do not change

//! \brief Defines the software pole location for the DC bus filter, rad/s

#define USER_DCBUS_POLE_rps (100.0) // 100.0 Default, do not change

//! \brief Defines the convergence factor for the estimator

//! \brief Do not change from default for FAST

#define USER_EST_KAPPAQ (1.5) // 1.5 Default, do not change

// **************************************************************************

// end the defines

//! \brief USER MOTOR & ID SETTINGS

// **************************************************************************

//! \brief Define each motor with a unique name and ID number

// BLDC & SMPM motors

#define Estun_EMJ_04APB22 101

#define Anaheim_BLY172S 102

#define My_Motor 104

#define hobby_3p5T 105

#define hobby_4p5T 106

#define small_hobby 107

#define teknic_2310P 108

#define hobbywing_ezrun_8p5T 109

#define eflite_helicopter_420 110

#define My_Motor_CB2065H2 111

#define My_Motor_TB 112

#define My_Motor_CB2065H 113

#define Bodine_34B3FEBL 114

#define Pittman_elcom_5233B599 115

#define medical_instrument 117

#define Test_Motor 118

#define My_Motor_ZMN 119

// IPM motors

// If user provides separate Ls-d, Ls-q

// else treat as SPM with user or identified average Ls

#define Belt_Drive_Washer_IPM 201

// ACIM motors

#define Marathon_5K33GN2A 301

#define Kinetek_YDQ1p3_4 302

#define LPKF_CAD_CAM 303

//! \brief Uncomment the motor which should be included at compile

//! \brief These motor ID settings and motor parameters are then available to be used by the control system

//! \brief Once your ideal settings and parameters are identified update the motor section here so it is available in the binary code

//#define USER_MOTOR Estun_EMJ_04APB22

#define USER_MOTOR My_Motor_ZMN

//#define USER_MOTOR hobby_3p5T

//#define USER_MOTOR hobby_4p5T

//#define USER_MOTOR My_Motor

//#define USER_MOTOR small_hobby

//#define USER_MOTOR Belt_Drive_Washer_IPM

//#define USER_MOTOR Marathon_5K33GN2A

//#define USER_MOTOR teknic_2310P

//#define USER_MOTOR hobbywing_ezrun_8p5T

//#define USER_MOTOR eflite_helicopter_420

//#define USER_MOTOR Bodine_34B3FEBL

//#define USER_MOTOR Pittman_elcom_5233B599

//#define USER_MOTOR medical_instrument

//#define USER_MOTOR Test_Motor

//#define USER_MOTOR Kinetek_YDQ1p3_4

//#define USER_MOTOR LPKF_CAD_CAM

#if (USER_MOTOR == Estun_EMJ_04APB22) // Name must match the motor #define

#define USER_MOTOR_TYPE MOTOR_Type_Pm // Motor_Type_Pm (All Synchronous: BLDC, PMSM, SMPM, IPM) or Motor_Type_Induction (Asynchronous ACI)

#define USER_MOTOR_NUM_POLE_PAIRS (4) // PAIRS, not total poles. Used to calculate user RPM from rotor Hz only

#define USER_MOTOR_Rr (NULL) // Induction motors only, else NULL

#define USER_MOTOR_Rs (2.303403) // Identified phase to neutral resistance in a Y equivalent circuit (Ohms, float)

#define USER_MOTOR_Ls_d (0.008464367) // For PM, Identified average stator inductance (Henry, float)

#define USER_MOTOR_Ls_q (0.008464367) // For PM, Identified average stator inductance (Henry, float)

#define USER_MOTOR_RATED_FLUX (0.38) // Identified TOTAL flux linkage between the rotor and the stator (V/Hz)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL) // Induction motors only, else NULL

#define USER_MOTOR_RES_EST_CURRENT (1.0) // During Motor ID, maximum current (Amperes, float) used for Rs estimation, 10-20% rated current

#define USER_MOTOR_IND_EST_CURRENT (-1.0) // During Motor ID, maximum current (negative Amperes, float) used for Ls estimation, use just enough to enable rotation

#define USER_MOTOR_MAX_CURRENT (3.82) // CRITICAL: Used during ID and run-time, sets a limit on the maximum current command output of the provided Speed PI Controller to the Iq controller

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0) // During Motor ID, maximum commanded speed (Hz, float), ~10% rated

#elif (USER_MOTOR == My_Motor_ZMN)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.25) //0.25

#define USER_MOTOR_Ls_d (0.0000269)

#define USER_MOTOR_Ls_q (0.0000269) //0.0000269

#define USER_MOTOR_RATED_FLUX (0.0235) //0.48V/Krpm * 60 /1000/极对数/1.732 0.00831

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.8)

#define USER_MOTOR_IND_EST_CURRENT (-0.6)

#define USER_MOTOR_MAX_CURRENT (4.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (100.0)

#elif (USER_MOTOR == Anaheim_BLY172S)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.3968007)

#define USER_MOTOR_Ls_d (0.0006708066)

#define USER_MOTOR_Ls_q (0.0006708066)

#define USER_MOTOR_RATED_FLUX (0.03433958)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#define USER_MOTOR_FREQ_LOW (10.0) // Hz - suggested to set to 10% of rated motor frequency

#define USER_MOTOR_FREQ_HIGH (100.0) // Hz - suggested to set to 100% of rated motor frequency

#define USER_MOTOR_FREQ_MAX (120.0) // Hz - suggested to set to 120% of rated motor frequency

#define USER_MOTOR_VOLT_MIN (3.0) // Volt - suggested to set to 15% of rated motor voltage

#define USER_MOTOR_VOLT_MAX (18.0) // Volt - suggested to set to 100% of rated motor voltage

#elif (USER_MOTOR == small_hobby)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (6)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (1.277921)

#define USER_MOTOR_Ls_d (0.0001230481)

#define USER_MOTOR_Ls_q (0.0001230481)

#define USER_MOTOR_RATED_FLUX (0.004417491)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.5)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (200.0)

#elif (USER_MOTOR == teknic_2310P)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.3654691)

#define USER_MOTOR_Ls_d (0.0002068772)

#define USER_MOTOR_Ls_q (0.0002068772)

#define USER_MOTOR_RATED_FLUX (0.04052209)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#elif (USER_MOTOR == hobby_3p5T)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.0149275)

#define USER_MOTOR_Ls_d (2.575126e-06)

#define USER_MOTOR_Ls_q (2.575126e-06)

#define USER_MOTOR_RATED_FLUX (0.003589415)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (15.0)

#define USER_MOTOR_IND_EST_CURRENT (-5.0)

#define USER_MOTOR_MAX_CURRENT (30.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (60.0)

#elif (USER_MOTOR == hobby_4p5T)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.01420126)

#define USER_MOTOR_Ls_d (6.466606e-06)

#define USER_MOTOR_Ls_q (6.466606e-06)

#define USER_MOTOR_RATED_FLUX (0.004845501)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (5.0)

#define USER_MOTOR_IND_EST_CURRENT (-5.0)

#define USER_MOTOR_MAX_CURRENT (10.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (60.0)

#elif (USER_MOTOR == hobbywing_ezrun_8p5T)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (1)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.01366183)

#define USER_MOTOR_Ls_d (1.556967e-05)

#define USER_MOTOR_Ls_q (1.556967e-05)

#define USER_MOTOR_RATED_FLUX (0.009272549)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (3.0)

#define USER_MOTOR_IND_EST_CURRENT (-2.0)

#define USER_MOTOR_MAX_CURRENT (10.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (60.0)

#elif (USER_MOTOR == eflite_helicopter_420)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (3)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.01953091)

#define USER_MOTOR_Ls_d (2.998549e-06)

#define USER_MOTOR_Ls_q (2.998549e-06)

#define USER_MOTOR_RATED_FLUX (0.003449948)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (3.0)

#define USER_MOTOR_IND_EST_CURRENT (-3.0)

#define USER_MOTOR_MAX_CURRENT (15.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (80.0)

#elif (USER_MOTOR == Bodine_34B3FEBL)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.1749963)

#define USER_MOTOR_Ls_d (0.000843199)

#define USER_MOTOR_Ls_q (0.000843199)

#define USER_MOTOR_RATED_FLUX (0.1139098)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (10.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#elif (USER_MOTOR == Pittman_elcom_5233B599)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.3675933)

#define USER_MOTOR_Ls_d (0.0001611779)

#define USER_MOTOR_Ls_q (0.0001611779)

#define USER_MOTOR_RATED_FLUX (0.1274101)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.5)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#elif (USER_MOTOR == medical_instrument)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.3858043)

#define USER_MOTOR_Ls_d (9.675411e-06)

#define USER_MOTOR_Ls_q (9.675411e-06)

#define USER_MOTOR_RATED_FLUX (0.006834516)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.5)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (10.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (100.0)

#elif (USER_MOTOR == Test_Motor)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (6)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.05910907)

#define USER_MOTOR_Ls_d (7.49289e-06)

#define USER_MOTOR_Ls_q (7.49289e-06)

#define USER_MOTOR_RATED_FLUX (0.003744936)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.5)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (8.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (100.0)

#elif (USER_MOTOR == My_Motor)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.38)

#define USER_MOTOR_Ls_d (0.000027)

#define USER_MOTOR_Ls_q (0.000027)

#define USER_MOTOR_RATED_FLUX (0.0288) //0.48V/Krpm * 60 /1000

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.8)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#elif (USER_MOTOR == My_Motor_TB)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.323500097) //0.38

#define USER_MOTOR_Ls_d (0.000814253988)

#define USER_MOTOR_Ls_q (0.000814253988) //0.000027

#define USER_MOTOR_RATED_FLUX (0.105179541) //0.48V/Krpm * 60 /1000/极对数/1.732 0.00831

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.7)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#elif (USER_MOTOR == My_Motor_CB2065H2)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.142) //0.14

#define USER_MOTOR_Ls_d (0.000013)

#define USER_MOTOR_Ls_q (0.000013) //0.000013

#define USER_MOTOR_RATED_FLUX (0.00831) //0.48V/Krpm * 60 /1000//1.732 0.00831

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (60.0)

#elif (USER_MOTOR == My_Motor_CB2065H)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.19) //0.38

#define USER_MOTOR_Ls_d (0.0000135)

#define USER_MOTOR_Ls_q (0.0000135) //0.000027

#define USER_MOTOR_RATED_FLUX (0.00836) //0.48V/Krpm * 60 /1000//1.732 0.00831

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (0.7)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (60.0)

#elif (USER_MOTOR == Belt_Drive_Washer_IPM)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (2.832002)

#define USER_MOTOR_Ls_d (0.0115)

#define USER_MOTOR_Ls_q (0.0135)

#define USER_MOTOR_RATED_FLUX (0.5022156)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (4.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#elif (USER_MOTOR == Marathon_5K33GN2A) // Name must match the motor #define

#define USER_MOTOR_TYPE MOTOR_Type_Induction // Motor_Type_Pm (All Synchronous: BLDC, PMSM, SMPM, IPM) or Motor_Type_Induction (Asynchronous ACI)

#define USER_MOTOR_NUM_POLE_PAIRS (2) // PAIRS, not total poles. Used to calculate user RPM from rotor Hz only

#define USER_MOTOR_Rr (5.508003) // Identified phase to neutral in a Y equivalent circuit (Ohms, float)

#define USER_MOTOR_Rs (10.71121) // Identified phase to neutral in a Y equivalent circuit (Ohms, float)

#define USER_MOTOR_Ls_d (0.05296588) // For Induction, Identified average stator inductance (Henry, float)

#define USER_MOTOR_Ls_q (0.05296588) // For Induction, Identified average stator inductance (Henry, float)

#define USER_MOTOR_RATED_FLUX (0.8165*220.0/60.0) // sqrt(2/3)* Rated V (line-line) / Rated Freq (Hz)

#define USER_MOTOR_MAGNETIZING_CURRENT (1.378) // Identified magnetizing current for induction motors, else NULL

#define USER_MOTOR_RES_EST_CURRENT (0.5) // During Motor ID, maximum current (Amperes, float) used for Rs estimation, 10-20% rated current

#define USER_MOTOR_IND_EST_CURRENT (NULL) // not used for induction

#define USER_MOTOR_MAX_CURRENT (2.0) // CRITICAL: Used during ID and run-time, sets a limit on the maximum current command output of the provided Speed PI Controller to the Iq controller

#define USER_MOTOR_FLUX_EST_FREQ_Hz (5.0) // During Motor ID, maximum commanded speed (Hz, float). Should always use 5 Hz for Induction.

#elif (USER_MOTOR == Kinetek_YDQ1p3_4)

#define USER_MOTOR_TYPE MOTOR_Type_Induction

#define USER_MOTOR_NUM_POLE_PAIRS (2)

#define USER_MOTOR_Rr (0.0)

#define USER_MOTOR_Rs (0.0)

#define USER_MOTOR_Ls_d (0.0)

#define USER_MOTOR_Ls_q (USER_MOTOR_Ls_d)

#define USER_MOTOR_RATED_FLUX (0.8165*16.0/120.0 - USER_MOTOR_Ls_d*USER_MOTOR_MAGNETIZING_CURRENT*2*MATH_PI)

#define USER_MOTOR_MAGNETIZING_CURRENT (0.0)

#define USER_MOTOR_RES_EST_CURRENT (20.0)

#define USER_MOTOR_IND_EST_CURRENT (NULL)

#define USER_MOTOR_MAX_CURRENT (40.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (5.0)

#elif (USER_MOTOR == LPKF_CAD_CAM)

#define USER_MOTOR_TYPE MOTOR_Type_Induction

#define USER_MOTOR_NUM_POLE_PAIRS (1)

#define USER_MOTOR_Rr (0.1832338)

#define USER_MOTOR_Rs (0.2610424)

#define USER_MOTOR_Ls_d (1.370321e-09)

#define USER_MOTOR_Ls_q (USER_MOTOR_Ls_d)

#define USER_MOTOR_RATED_FLUX (0.8165*30.0/1000.0 - USER_MOTOR_Ls_d*USER_MOTOR_MAGNETIZING_CURRENT*2*MATH_PI)

#define USER_MOTOR_MAGNETIZING_CURRENT (3.386112)

#define USER_MOTOR_RES_EST_CURRENT (3.0)

#define USER_MOTOR_IND_EST_CURRENT (NULL)

#define USER_MOTOR_MAX_CURRENT (5.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#else

#error No motor type specified

#endif

#ifndef USER_MOTOR

#error Motor is not defined in user.h

#endif

#ifndef USER_MOTOR_TYPE

#error The motor type is not defined in user.h

#endif

#ifndef USER_MOTOR_NUM_POLE_PAIRS

#error Number of motor pole pairs is not defined in user.h

#endif

#ifndef USER_MOTOR_Rr

#error The rotor resistance is not defined in user.h

#endif

#ifndef USER_MOTOR_Rs

#error The stator resistance is not defined in user.h

#endif

#ifndef USER_MOTOR_Ls_d

#error The direct stator inductance is not defined in user.h

#endif

#ifndef USER_MOTOR_Ls_q

#error The quadrature stator inductance is not defined in user.h

#endif

#ifndef USER_MOTOR_RATED_FLUX

#error The rated flux of motor is not defined in user.h

#endif

#ifndef USER_MOTOR_MAGNETIZING_CURRENT

#error The magnetizing current is not defined in user.h

#endif

#ifndef USER_MOTOR_RES_EST_CURRENT

#error The resistance estimation current is not defined in user.h

#endif

#ifndef USER_MOTOR_IND_EST_CURRENT

#error The inductance estimation current is not defined in user.h

#endif

#ifndef USER_MOTOR_MAX_CURRENT

#error The maximum current is not defined in user.h

#endif

#ifndef USER_MOTOR_FLUX_EST_FREQ_Hz

#error The flux estimation frequency is not defined in user.h

#endif

// **************************************************************************

// the functions

//! \brief Sets the user parameter values

//! \param[in] pUserParams The pointer to the user param structure

extern void USER_setParams(USER_Params *pUserParams);

//! \brief Checks for errors in the user parameter values

//! \param[in] pUserParams The pointer to the user param structure

extern void USER_checkForErrors(USER_Params *pUserParams);

//! \brief Gets the error code in the user parameters

//! \param[in] pUserParams The pointer to the user param structure

//! \return The error code

extern USER_ErrorCode_e USER_getErrorCode(USER_Params *pUserParams);

//! \brief Sets the error code in the user parameters

//! \param[in] pUserParams The pointer to the user param structure

//! \param[in] errorCode The error code

extern void USER_setErrorCode(USER_Params *pUserParams,const USER_ErrorCode_e errorCode);

//! \brief Recalculates Inductances with the correct Q Format

//! \param[in] handle The controller (CTRL) handle

extern void USER_softwareUpdate1p6(CTRL_Handle handle);

//! \brief Updates Id and Iq PI gains

//! \param[in] handle The controller (CTRL) handle

extern void USER_calcPIgains(CTRL_Handle handle);

//! \brief Computes the scale factor needed to convert from torque created by Ld, Lq, Id and Iq, from per unit to Nm

//! \return The scale factor to convert torque from (Ld - Lq) * Id * Iq from per unit to Nm, in IQ24 format

extern _iq USER_computeTorque_Ls_Id_Iq_pu_to_Nm_sf(void);

//! \brief Computes the scale factor needed to convert from torque created by flux and Iq, from per unit to Nm

//! \return The scale factor to convert torque from Flux * Iq from per unit to Nm, in IQ24 format

extern _iq USER_computeTorque_Flux_Iq_pu_to_Nm_sf(void);

//! \brief Computes the scale factor needed to convert from per unit to Wb

//! \return The scale factor to convert from flux per unit to flux in Wb, in IQ24 format

extern _iq USER_computeFlux_pu_to_Wb_sf(void);

//! \brief Computes the scale factor needed to convert from per unit to V/Hz

//! \return The scale factor to convert from flux per unit to flux in V/Hz, in IQ24 format

extern _iq USER_computeFlux_pu_to_VpHz_sf(void);

//! \brief Computes Flux in Wb or V/Hz depending on the scale factor sent as parameter

//! \param[in] handle The controller (CTRL) handle

//! \param[in] sf The scale factor to convert flux from per unit to Wb or V/Hz

//! \return The flux in Wb or V/Hz depending on the scale factor sent as parameter, in IQ24 format

extern _iq USER_computeFlux(CTRL_Handle handle, const _iq sf);

//! \brief Computes Torque in Nm

//! \param[in] handle The controller (CTRL) handle

//! \param[in] torque_Flux_sf The scale factor to convert torque from (Ld - Lq) * Id * Iq from per unit to Nm

//! \param[in] torque_Ls_sf The scale factor to convert torque from Flux * Iq from per unit to Nm

//! \return The torque in Nm, in IQ24 format

extern _iq USER_computeTorque_Nm(CTRL_Handle handle, const _iq torque_Flux_sf, const _iq torque_Ls_sf);

//! \brief Computes Torque in lbin

//! \param[in] handle The controller (CTRL) handle

//! \param[in] torque_Flux_sf The scale factor to convert torque from (Ld - Lq) * Id * Iq from per unit to lbin

//! \param[in] torque_Ls_sf The scale factor to convert torque from Flux * Iq from per unit to lbin

//! \return The torque in lbin, in IQ24 format

extern _iq USER_computeTorque_lbin(CTRL_Handle handle, const _iq torque_Flux_sf, const _iq torque_Ls_sf);

#ifdef __cplusplus

}

#endif // extern "C"

//@} // ingroup

#endif // end of _USER_H_ definition