请注意,本文内容源自机器翻译,可能存在语法或其它翻译错误,仅供参考。如需获取准确内容,请参阅链接中的英语原文或自行翻译。

器件型号:TMS320F28069M-Q1 void RVP_setupPosPlan6Step_ModifyPlanVelocity(float Krpm)

{

_iq VelLim, AccLim, DecLim;

_iq20 JrkLim;

uint16_t FromState,ToState,AndOr,CondIdx1,CondIdx2;

ST_Obj *stObj = (ST_Obj *) RVP_stHandle[5];

STPOSPLAN_getCfgTran(stObj->posPlanHandle, 1, &FromState, &ToState, &AndOr, &CondIdx1, &CondIdx2, &VelLim, &AccLim, &DecLim, &JrkLim); // From StateB to StateC

RVP_DisplayPosPlan(VelLim,AccLim,DecLim,JrkLim);

VelLim = _IQ24(Krpm * ST_SPEED_PU_PER_KRPM); // ST_SPEED_PU_PER_KRPM =0.1333

STPOSPLAN_setCfgTran(stObj->posPlanHandle, 1, FromState, ToState, (ST_PlanCond_e) AndOr, CondIdx1, CondIdx2, VelLim, AccLim, DecLim, JrkLim); // From StateB to StateC

STPOSPLAN_getCfgTran(stObj->posPlanHandle, 1, &FromState, &ToState, &AndOr, &CondIdx1, &CondIdx2, &VelLim, &AccLim, &DecLim, &JrkLim);

RVP_DisplayPosPlan(VelLim,AccLim,DecLim,JrkLim);

}

void RVP_DisplayPosPlan(_iq VelLim, _iq AccLim, _iq DecLim, _iq20 JrkLim)

{

zprintf("Velim : %Q24\n",VelLim);

zprintf("AccLim: %Q24\n",AccLim);

zprintf("DecLim: %Q24\n",DecLim);

zprintf("JrkLim: %Q20\n",JrkLim);

zprintf("---------------------\n");

}

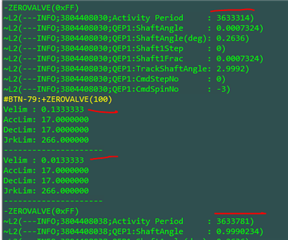

附加的代码、用于在启动前针对不同的速度参数修改 VeLim。 我尝试了不同的速度、但它不符合要求。 下面是终端快照,活动周期是完成计划所需的时间,应该有所不同(以及观察电机旋转情况).... 但它不在100rpm 到1000rpm 之间

当我为每个调试闪存更改其中的 VelLim 并运行时、以下代码起作用。

我已阅读《Instant Spin 用户指南》、但未找到原因。

void RVP_setupPosPlan_Plan6_ValveZero(ST_Handle sthandle)

{

_iq velMax, accMax, jrkMax; // DWORD = 32 bit.

_iq velLim, accLim, decLim;

_iq20 jrkLim;

ST_Obj *stObj = (ST_Obj *)sthandle;

memset(stPosPlanCfgArray_Plan6,0,sizeof(stPosPlanCfgArray_Plan6));

// Pass the configuration array pointer into SpinTAC Position Plan

STPOSPLAN_setCfgArray(stObj->posPlanHandle, &stPosPlanCfgArray_Plan6[0], sizeof(stPosPlanCfgArray_Plan6), 0, 0, 0, 4, 4);

//----------------------------------------------------------------------------

// Establish the Velocity, Acceleration, Deceleration, and Jerk Maximums

//----------------------------------------------------------------------------

velMax = _IQ24(2.5 * ST_SPEED_PU_PER_KRPM); // 1000 RPM to PU number. = 0.333 // Limit:0.0 to +1.0

accMax = _IQ24(17.0); // Max Accel, should this be 120, not 127?

jrkMax = _IQ20(266.0); // Max Jerk

//----------------------------------------------------------------------------

velLim = _IQ24(0.05 * ST_SPEED_PU_PER_KRPM); // ST_SPEED_PU_PER_KRPM =0.1333 // Limit:0.0 to 1.0

accLim = _IQ24(17.0); //_IQ24(1.0 * ST_SPEED_PU_PER_KRPM); 17 is very max Accel for Q24 // Limit:0.001 to 120.0

decLim = _IQ24(17.0); //_IQ24(1.0 * ST_SPEED_PU_PER_KRPM); // Limit:0.001 to 120.0

//----------------------------------------------------------------------------Jerk via ST_MOVE_CUR_STCRV

jrkLim = _IQ20(266.0); // Max is 266 under ST_MOVE_CUR_STCRV only. // Limit:0.0005, 2000.0

//gMotorVars.SpinTAC.PosMoveCurveType: See pobj->PosMoveCurveType[5] in RVP_MotorPlan.c

STPOSPLAN_setCfg(stObj->posPlanHandle, _IQ(ST_SAMPLE_TIME), false); // Do not repeat Loop.

STPOSPLAN_setCfgHaltState(stObj->posPlanHandle, 0, 0, velMax, accMax, jrkMax, 1000L); // Configure halt state: PosStep[MRev], PosStepFrac[MRev], VelEnd, AccMax, JrkMax, Timer

//Example: STPOSPLAN_addCfgState(handle, PosStep[MRev], PosStepFrac[MRev], StateTimer[ticks]);

STPOSPLAN_addCfgState(stObj->posPlanHandle, 0, 0, 1L); // StateIdx0: A

STPOSPLAN_addCfgState(stObj->posPlanHandle, +6, 0, 1L); // StateIdx1: B // This does nothing since it now controlled by STEP/FRAC code.

STPOSPLAN_addCfgState(stObj->posPlanHandle, 0, 0, 1L); // StateIdx2: C

//Example: STPOSPLAN_addCfgTran(handle, FromState, ToState, CondOption, CondIdx1, CondiIdx2, VelLim[pups], AccLim[pups2], DecLim[pups2], JrkLim[pups3]);

// NOTE: The deceleration limit must be set between the following bounds [acceleration limit, 10*acceleration limit]

STPOSPLAN_addCfgTran(stObj->posPlanHandle, 0, 1, ST_COND_NC, 0, 0, velLim, accLim, decLim, jrkLim); // From StateA to StateB

STPOSPLAN_addCfgTran(stObj->posPlanHandle, 1, 2, ST_COND_NC, 0, 0, velLim, accLim, decLim, jrkLim); // From StateB to StateC

STPOSPLAN_addCfgTran(stObj->posPlanHandle, 2, 0, ST_COND_NC, 0, 0, velLim, accLim, decLim, jrkLim); // From StateD to StateA

}