主题中讨论的其他器件: C2000WARE

您好!

该实验示例使用了 PWM 时间周期数宏、我认为这是用于使用 LAUNCHXL-F280025C 的100Mhz 系统时钟。

#define USER_M1_PWM_TBPRD_NUM (uint16_t)(USER_SYSTEM_FREQ_MHz * 1000.0f / USER_M1_PWM_FREQ_kHz / 2.0f)

HAL_setupPWMs ()正在使用该宏设置 pwmPeriodCycles。

uint16_t pwmPeriodCycles =(uint16_t)(USER_M1_PWM_TBPRD_NUM);

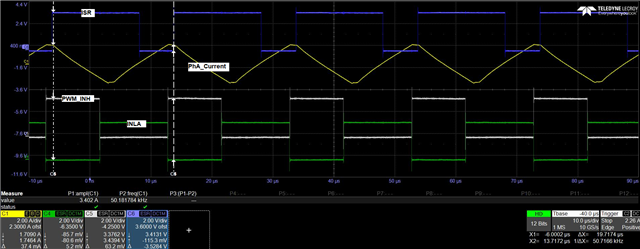

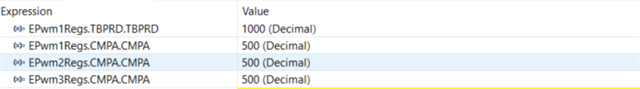

我计划在定制电路板上以50kHz PWM 和200MHz 的系统时钟运行。 对于200MHz 系统时钟、这个宏的建议值是多少? 我尝试了几种组合。 例如、如果我在宏中除以4以补偿系统时钟加倍、那么 我的 PWM 输出为 50Hz、但示例未运行。 TBPRD 为1000、CMPA 为500。

如果我尝试将 TBPRD 设置为2500、将 CMPA 设置为1250 (除以1.6)、则我的 输出 PWM 为20kHz、而目标 PWM 为50kHz。

void HAL_setupPWMs(HAL_MTR_Handle handle)

{

HAL_MTR_Obj *obj = (HAL_MTR_Obj *)handle;

uint16_t cnt;

uint16_t pwmPeriodCycles = (uint16_t)(USER_M1_PWM_TBPRD_NUM);

uint16_t numPWMTicksPerISRTick = USER_M1_NUM_PWM_TICKS_PER_ISR_TICK;

// disable the ePWM module time base clock sync signal

// to synchronize all of the PWMs

SysCtl_disablePeripheral(SYSCTL_PERIPH_CLK_TBCLKSYNC);

// turns off the outputs of the EPWM peripherals which will put the power

// switches into a high impedance state.

EPWM_forceTripZoneEvent(obj->pwmHandle[0], EPWM_TZ_FORCE_EVENT_OST);

EPWM_forceTripZoneEvent(obj->pwmHandle[1], EPWM_TZ_FORCE_EVENT_OST);

EPWM_forceTripZoneEvent(obj->pwmHandle[2], EPWM_TZ_FORCE_EVENT_OST);

#if defined(BSXL8323RS_REVA) || defined(BSXL8323RH_REVB) || \

defined(BSXL8353RS_REVA) || defined(BSXL8316RT_REVA) || \

defined(BSXL3PHGAN_REVA) || defined(HVMTRPFC_REV1P1) || \

defined(DRV8329AEVM_REVA)

for(cnt=0; cnt<3; cnt++)

{

// setup the Time-Base Control Register (TBCTL)

EPWM_setTimeBaseCounterMode(obj->pwmHandle[cnt],

EPWM_COUNTER_MODE_UP_DOWN);

EPWM_disablePhaseShiftLoad(obj->pwmHandle[cnt]);

EPWM_setPeriodLoadMode(obj->pwmHandle[cnt], EPWM_PERIOD_DIRECT_LOAD);

/* Commented JS

EPWM_enableSyncOutPulseSource(obj->pwmHandle[cnt],

EPWM_SYNC_OUT_PULSE_ON_SOFTWARE);

*/

EPWM_setClockPrescaler(obj->pwmHandle[cnt], EPWM_CLOCK_DIVIDER_2,

EPWM_HSCLOCK_DIVIDER_2);

EPWM_setCountModeAfterSync(obj->pwmHandle[cnt],

EPWM_COUNT_MODE_UP_AFTER_SYNC);

EPWM_setEmulationMode(obj->pwmHandle[cnt], EPWM_EMULATION_FREE_RUN);

// setup the Timer-Based Phase Register (TBPHS)

EPWM_setPhaseShift(obj->pwmHandle[cnt], 0);

// setup the Time-Base Counter Register (TBCTR)

EPWM_setTimeBaseCounter(obj->pwmHandle[cnt], 0);

// setup the Time-Base Period Register (TBPRD)

// set to zero initially

EPWM_setTimeBasePeriod(obj->pwmHandle[cnt], 0);

// setup the Counter-Compare Control Register (CMPCTL)

EPWM_setCounterCompareShadowLoadMode(obj->pwmHandle[cnt],

EPWM_COUNTER_COMPARE_A,

EPWM_COMP_LOAD_ON_CNTR_ZERO);

EPWM_setCounterCompareShadowLoadMode(obj->pwmHandle[cnt],

EPWM_COUNTER_COMPARE_B,

EPWM_COMP_LOAD_ON_CNTR_ZERO);

EPWM_setCounterCompareShadowLoadMode(obj->pwmHandle[cnt],

EPWM_COUNTER_COMPARE_C,

EPWM_COMP_LOAD_ON_CNTR_ZERO);

EPWM_setCounterCompareShadowLoadMode(obj->pwmHandle[cnt],

EPWM_COUNTER_COMPARE_D,

EPWM_COMP_LOAD_ON_CNTR_ZERO);

#if defined(MOTOR1_ISBLDC)

// setup the Action-Qualifier Output A Register (AQCTLA)

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_HIGH,

EPWM_AQ_OUTPUT_ON_TIMEBASE_UP_CMPA);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_LOW,

EPWM_AQ_OUTPUT_ON_TIMEBASE_DOWN_CMPA);

// setup the Action-qualifier Continuous Software Force Register (AQCSFRC)

EPWM_setActionQualifierContSWForceAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_B,

EPWM_AQ_SW_OUTPUT_LOW);

// setup the Dead-Band Generator Control Register (DBCTL)

EPWM_setDeadBandDelayMode(obj->pwmHandle[cnt], EPWM_DB_RED, false);

EPWM_setDeadBandDelayMode(obj->pwmHandle[cnt], EPWM_DB_FED, false);

#else //!MOTOR1_ISBLDC

#if defined(MOTOR1_DCLINKSS)

// setup the Action-Qualifier Output A Register (AQCTLA)

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_HIGH,

EPWM_AQ_OUTPUT_ON_TIMEBASE_UP_CMPA);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_LOW,

EPWM_AQ_OUTPUT_ON_TIMEBASE_DOWN_CMPB);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_LOW,

EPWM_AQ_OUTPUT_ON_TIMEBASE_ZERO);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_HIGH,

EPWM_AQ_OUTPUT_ON_TIMEBASE_PERIOD);

#else // !(MOTOR1_DCLINKSS)

// setup the Action-Qualifier Output A Register (AQCTLA)

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_HIGH,

EPWM_AQ_OUTPUT_ON_TIMEBASE_UP_CMPA);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_HIGH,

EPWM_AQ_OUTPUT_ON_TIMEBASE_PERIOD);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_LOW,

EPWM_AQ_OUTPUT_ON_TIMEBASE_DOWN_CMPA);

EPWM_setActionQualifierAction(obj->pwmHandle[cnt],

EPWM_AQ_OUTPUT_A,

EPWM_AQ_OUTPUT_LOW,

EPWM_AQ_OUTPUT_ON_TIMEBASE_ZERO);

#endif // !(MOTOR1_DCLINKSS)

// setup the Dead-Band Generator Control Register (DBCTL)

EPWM_setDeadBandDelayMode(obj->pwmHandle[cnt], EPWM_DB_RED, true);

EPWM_setDeadBandDelayMode(obj->pwmHandle[cnt], EPWM_DB_FED, true);

// select EPWMA as the input to the dead band generator

EPWM_setRisingEdgeDeadBandDelayInput(obj->pwmHandle[cnt],

EPWM_DB_INPUT_EPWMA);

// configure the right polarity for active high complementary config.

EPWM_setDeadBandDelayPolarity(obj->pwmHandle[cnt],

EPWM_DB_RED,

EPWM_DB_POLARITY_ACTIVE_HIGH);

EPWM_setDeadBandDelayPolarity(obj->pwmHandle[cnt],

EPWM_DB_FED,

EPWM_DB_POLARITY_ACTIVE_LOW);

// setup the Dead-Band Rising Edge Delay Register (DBRED)

EPWM_setRisingEdgeDelayCount(obj->pwmHandle[cnt], MTR1_PWM_DBRED_CNT);

// setup the Dead-Band Falling Edge Delay Register (DBFED)

EPWM_setFallingEdgeDelayCount(obj->pwmHandle[cnt], MTR1_PWM_DBFED_CNT);

#endif //!MOTOR1_ISBLDC

// setup the PWM-Chopper Control Register (PCCTL)

EPWM_disableChopper(obj->pwmHandle[cnt]);

// setup the Trip Zone Select Register (TZSEL)

EPWM_disableTripZoneSignals(obj->pwmHandle[cnt], HAL_TZSEL_SIGNALS_ALL);

}

// BSXL8323RS_REVA || BSXL8323RH_REVB || BSXL8353RS_REVA || \

// BSXL8316RT_REVA || BSXL3PHGAN_REVA || HVMTRPFC_REV1P1 || \

// DRV8329AEVM_REVA

#else

#error The PWM is not configured for motor_1 control

#endif // boards

#if defined(MOTOR1_ISBLDC)

// setup the Event Trigger Selection Register (ETSEL)

EPWM_setInterruptSource(obj->pwmHandle[0], EPWM_INT_TBCTR_ZERO);

EPWM_disableInterrupt(obj->pwmHandle[0]);

EPWM_setADCTriggerSource(obj->pwmHandle[0],

EPWM_SOC_A, EPWM_SOC_TBCTR_ZERO);

EPWM_enableADCTrigger(obj->pwmHandle[0], EPWM_SOC_A);

EPWM_setADCTriggerSource(obj->pwmHandle[0],

EPWM_SOC_B, EPWM_SOC_TBCTR_U_CMPB);

EPWM_enableADCTrigger(obj->pwmHandle[0], EPWM_SOC_B);

#elif defined(MOTOR1_DCLINKSS)

// setup the Event Trigger Selection Register (ETSEL)

EPWM_setInterruptSource(obj->pwmHandle[0], EPWM_INT_TBCTR_ZERO);

EPWM_enableInterrupt(obj->pwmHandle[0]);

EPWM_setADCTriggerSource(obj->pwmHandle[0],

EPWM_SOC_A, EPWM_SOC_TBCTR_D_CMPC);

EPWM_enableADCTrigger(obj->pwmHandle[0], EPWM_SOC_A);

// ADC SOC trigger for the 1st dc-link current sampling

EPWM_setADCTriggerSource(obj->pwmHandle[1],

EPWM_SOC_A,

EPWM_SOC_TBCTR_U_CMPC);

EPWM_enableADCTrigger(obj->pwmHandle[1], EPWM_SOC_A);

// ADC SOC trigger for the 2nd dc-link current sampling

EPWM_setADCTriggerSource(obj->pwmHandle[1],

EPWM_SOC_B,

EPWM_SOC_TBCTR_U_CMPD);

EPWM_enableADCTrigger(obj->pwmHandle[1], EPWM_SOC_B);

// ADC SOC trigger for the 3rd dc-link current sampling

EPWM_setADCTriggerSource(obj->pwmHandle[2],

EPWM_SOC_A,

EPWM_SOC_TBCTR_D_CMPC);

EPWM_enableADCTrigger(obj->pwmHandle[2], EPWM_SOC_A);

// ADC SOC trigger for the 4th dc-link current sampling

EPWM_setADCTriggerSource(obj->pwmHandle[2],

EPWM_SOC_B,

EPWM_SOC_TBCTR_D_CMPD);

EPWM_enableADCTrigger(obj->pwmHandle[2], EPWM_SOC_B);

#else //!(MOTOR1_ISBLDC || MOTOR1_DCLINKSS)

// setup the Event Trigger Selection Register (ETSEL)

EPWM_setInterruptSource(obj->pwmHandle[0], EPWM_INT_TBCTR_ZERO);

EPWM_enableInterrupt(obj->pwmHandle[0]);

EPWM_setADCTriggerSource(obj->pwmHandle[0],

EPWM_SOC_A, EPWM_SOC_TBCTR_D_CMPC);

EPWM_enableADCTrigger(obj->pwmHandle[0], EPWM_SOC_A);

#endif // !(MOTOR1_ISBLDC || MOTOR1_DCLINKSS)

// setup the Event Trigger Prescale Register (ETPS)

if(numPWMTicksPerISRTick > 15)

{

numPWMTicksPerISRTick = 15;

}

else if(numPWMTicksPerISRTick < 1)

{

numPWMTicksPerISRTick = 1;

}

EPWM_setInterruptEventCount(obj->pwmHandle[0], numPWMTicksPerISRTick);

EPWM_setADCTriggerEventPrescale(obj->pwmHandle[0], EPWM_SOC_A,

numPWMTicksPerISRTick);

EPWM_setADCTriggerEventPrescale(obj->pwmHandle[0], EPWM_SOC_B,

numPWMTicksPerISRTick);

#if defined(MOTOR1_DCLINKSS)

EPWM_setADCTriggerEventPrescale(obj->pwmHandle[1], EPWM_SOC_A,

numPWMTicksPerISRTick);

EPWM_setADCTriggerEventPrescale(obj->pwmHandle[1], EPWM_SOC_B,

numPWMTicksPerISRTick);

EPWM_setADCTriggerEventPrescale(obj->pwmHandle[2], EPWM_SOC_A,

numPWMTicksPerISRTick);

EPWM_setADCTriggerEventPrescale(obj->pwmHandle[2], EPWM_SOC_B,

numPWMTicksPerISRTick);

#endif //MOTOR1_DCLINKSS

// setup the Event Trigger Clear Register (ETCLR)

EPWM_clearEventTriggerInterruptFlag(obj->pwmHandle[0]);

EPWM_clearADCTriggerFlag(obj->pwmHandle[0], EPWM_SOC_A);

EPWM_clearADCTriggerFlag(obj->pwmHandle[0], EPWM_SOC_B);

// since the PWM is configured as an up/down counter, the period register is

// set to one-half of the desired PWM period

EPWM_setTimeBasePeriod(obj->pwmHandle[0], pwmPeriodCycles);

EPWM_setTimeBasePeriod(obj->pwmHandle[1], pwmPeriodCycles);

EPWM_setTimeBasePeriod(obj->pwmHandle[2], pwmPeriodCycles);

// write the PWM data value for ADC trigger

EPWM_setCounterCompareValue(obj->pwmHandle[0], EPWM_COUNTER_COMPARE_C, 10);

// write the PWM data value for ADC trigger

#if defined(MOTOR1_DCLINKSS)

EPWM_clearADCTriggerFlag(obj->pwmHandle[1], EPWM_SOC_A);

EPWM_clearADCTriggerFlag(obj->pwmHandle[1], EPWM_SOC_B);

EPWM_clearADCTriggerFlag(obj->pwmHandle[2], EPWM_SOC_A);

EPWM_clearADCTriggerFlag(obj->pwmHandle[2], EPWM_SOC_B);

EPWM_setCounterCompareValue(obj->pwmHandle[1],

EPWM_COUNTER_COMPARE_C, pwmPeriodCycles>>1);

EPWM_setCounterCompareValue(obj->pwmHandle[1],

EPWM_COUNTER_COMPARE_D, pwmPeriodCycles>>1);

EPWM_setCounterCompareValue(obj->pwmHandle[2],

EPWM_COUNTER_COMPARE_C, pwmPeriodCycles>>1);

EPWM_setCounterCompareValue(obj->pwmHandle[2],

EPWM_COUNTER_COMPARE_D, pwmPeriodCycles>>1);

#endif //MOTOR1_DCLINKSS

// enable the ePWM module time base clock sync signal

SysCtl_enablePeripheral(SYSCTL_PERIPH_CLK_TBCLKSYNC);

return;

} // end of HAL_setupPWMs() function