大家好、我一直在尝试使用适用于 MSP430FR4133的 ADC 模块实施模拟双轴操纵杆、我已经开始连接两个电位器进行测试。 我已经遵循了 slac625h 库中的示例代码"msp430fr413x_adc10_10.c"示例。 我唯一更改的是从8位转换更改为10位转换、以及 int 格式、ADCSRF_0更改为 AVCC、AVSS。

代码:

#include <msp430.h>

unsigned int ADC_Result[3]; // 8-bit ADC conversion result array

unsigned int i;

int main(void)

{

WDTCTL = WDTPW | WDTHOLD; // Stop WDT

// Configure ADC A0~2 pins

SYSCFG2 |= ADCPCTL0 | ADCPCTL1 | ADCPCTL2;

// Disable the GPIO power-on default high-impedance mode to activate

// previously configured port settings

PM5CTL0 &= ~LOCKLPM5;

// Configure ADC

ADCCTL0 |= ADCSHT_2 | ADCON; // 16ADCclks, ADC ON

ADCCTL1 |= ADCSHP | ADCSSEL_1 | ADCSHS_2 | ADCCONSEQ_3; // ADC clock MODCLK, sampling timer, TA1.1B trig.,repeat sequence

ADCCTL2 |= ADCRES; // 10-bit conversion results

ADCMCTL0 |= ADCINCH_2 | ADCSREF_0; // A0~2(EoS); Vref=Vcc

ADCIE |= ADCIE0; // Enable ADC conv complete interrupt

// Configure reference

PMMCTL0_H = PMMPW_H; // Unlock the PMM registers

PMMCTL2 |= INTREFEN; // Enable internal reference

__delay_cycles(400); // Delay for reference settling

__no_operation();

// Configure TA1.1B as ADC trigger signal

// Note: The TA1.1B is configured for 200us 50% PWM, which will trigger ADC

// sample-and-conversion every 200us. The period of TA1.1B trigger event

// should be more than the time period taken for ADC sample-and-conversion

// and ADC interrupt service routine of each channel, which is about 57us in this code

TA1CCR0 = 200-1; // PWM Period, 200us

TA1CCTL1 = OUTMOD_7; // CCR1 reset/set

TA1CCR1 = 100; // CCR1 PWM duty cycle, 50%

TA1CTL = TASSEL__SMCLK | MC__UP | TACLR; // SMCLK, up mode, clear TAR

while(1)

{

i = 2;

ADCCTL0 |= ADCENC; // Enable ADC

TA1CTL |= TACLR; // Clear TAR to start the ADC sample-and-conversion

__bis_SR_register(LPM0_bits | GIE); // Enter LPM0 w/ interrupts

__no_operation(); // Only for debugger

}

}

// ADC interrupt service routine

#if defined(__TI_COMPILER_VERSION__) || defined(__IAR_SYSTEMS_ICC__)

#pragma vector=ADC_VECTOR

__interrupt void ADC_ISR(void)

#elif defined(__GNUC__)

void __attribute__ ((interrupt(ADC_VECTOR))) ADC_ISR (void)

#else

#error Compiler not supported!

#endif

{

switch(__even_in_range(ADCIV,ADCIV_ADCIFG))

{

case ADCIV_NONE:

break;

case ADCIV_ADCOVIFG:

break;

case ADCIV_ADCTOVIFG:

break;

case ADCIV_ADCHIIFG:

break;

case ADCIV_ADCLOIFG:

break;

case ADCIV_ADCINIFG:

break;

case ADCIV_ADCIFG:

ADC_Result[i] = ADCMEM0;

if(i == 0)

{

__no_operation(); // Only for debugger

i = 2;

}

else

{

i--;

}

break;

default:

break;

}

}

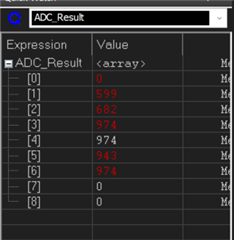

我在过去几天一直在这里,但我似乎不能完全包裹我的头,为什么 A0读数似乎不是从电位器正确的读数。 但 A1读数似乎是完美的。 A2仅为 P1.2按钮(工作正常;按下时显示0)。

下面是我的接线图:

(为糟糕的图表道歉)

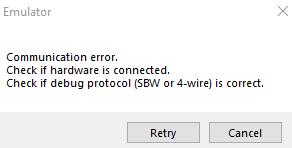

我还注意到另一个异常情况、如果我在 A0上将电位器修整得太远(10k)、IAR 会向我显示以下错误、并且我的程序在调试期间只是挂起:

我尝试使用替代电位计、但错误相同。

非常感谢您的参与!

亚伦