Other Parts Discussed in Thread: TMDSCNCD28035, CONTROLSUITE

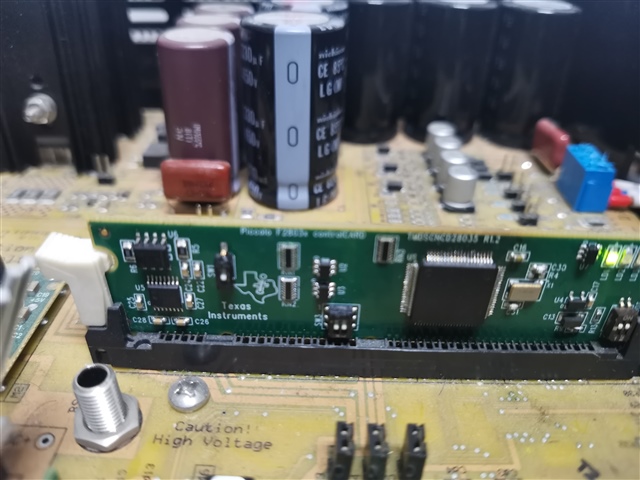

使用官方TMDSHVMTRPFCKIT高电压电机控制和 PFC 开发者套件调试level3时突然出现这样,请问是什么原因,该如何解决?(Piccolo TMDSCNCD28035 controlCARD只有LED1亮)

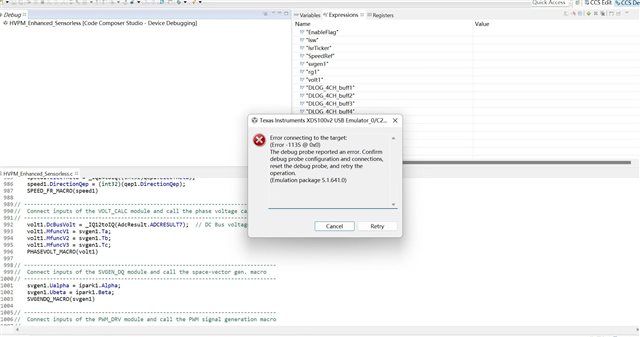

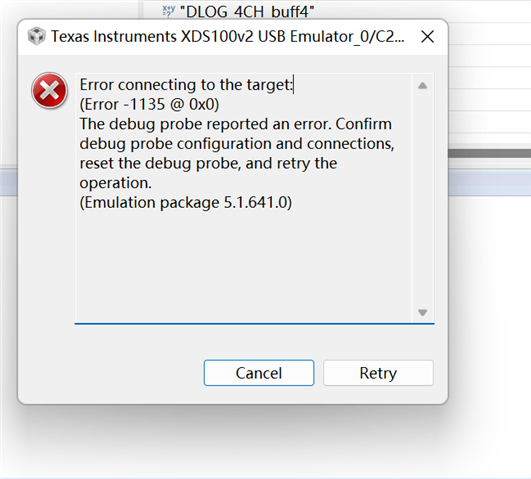

这是Debug error:

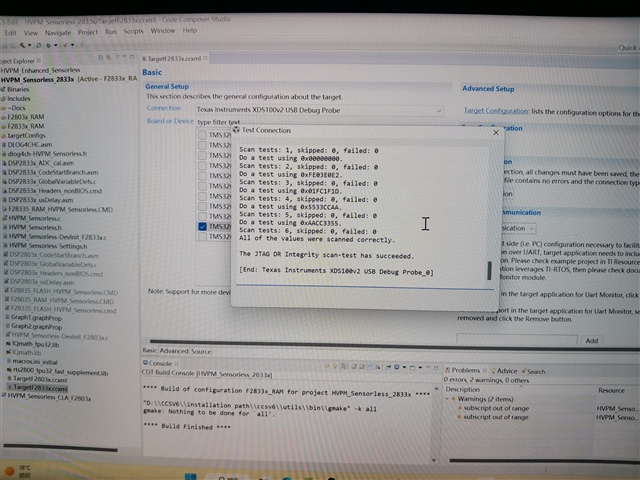

这是Test Connection 的结果:

[Start: Texas Instruments XDS100v2 USB Emulator_0]

Execute the command:

%ccs_base%/common/uscif/dbgjtag -f %boarddatafile% -rv -o -F inform,logfile=yes -S pathlength -S integrity

[Result]

-----[Print the board config pathname(s)]------------------------------------

C:\Users\27683\AppData\Local\TEXASI~1\CCS\

INSTAL~1\5\0\BrdDat\testBoard.dat

-----[Print the reset-command software log-file]-----------------------------

This utility has selected a 100- or 510-class product.

This utility will load the adapter 'jioserdesusb.dll'.

The library build date was 'Feb 18 2015'.

The library build time was '23:56:50'.

The library package version is '5.1.641.0'.

The library component version is '35.34.40.0'.

The controller does not use a programmable FPGA.

The controller has a version number of '4' (0x00000004).

The controller has an insertion length of '0' (0x00000000).

This utility will attempt to reset the controller.

This utility has successfully reset the controller.

-----[Print the reset-command hardware log-file]-----------------------------

The scan-path will be reset by toggling the JTAG TRST signal.

The controller is the FTDI FT2232 with USB interface.

The link from controller to target is direct (without cable).

The software is configured for FTDI FT2232 features.

The controller cannot monitor the value on the EMU[0] pin.

The controller cannot monitor the value on the EMU[1] pin.

The controller cannot control the timing on output pins.

The controller cannot control the timing on input pins.

The scan-path link-delay has been set to exactly '0' (0x0000).

-----[The log-file for the JTAG TCLK output generated from the PLL]----------

There is no hardware for programming the JTAG TCLK frequency.

-----[Measure the source and frequency of the final JTAG TCLKR input]--------

There is no hardware for measuring the JTAG TCLK frequency.

-----[Perform the standard path-length test on the JTAG IR and DR]-----------

This path-length test uses blocks of 512 32-bit words.

The test for the JTAG IR instruction path-length failed.

The JTAG IR instruction scan-path is stuck-at-ones.

The test for the JTAG DR bypass path-length failed.

The JTAG DR bypass scan-path is stuck-at-ones.

-----[Perform the Integrity scan-test on the JTAG IR]------------------------

This test will use blocks of 512 32-bit words.

This test will be applied just once.

Do a test using 0xFFFFFFFF.

Scan tests: 1, skipped: 0, failed: 0

Do a test using 0x00000000.

Test 2 Word 0: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 1: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 2: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 3: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 4: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 5: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 6: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 7: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

The details of the first 8 errors have been provided.

The utility will now report only the count of failed tests.

Scan tests: 2, skipped: 0, failed: 1

Do a test using 0xFE03E0E2.

Scan tests: 3, skipped: 0, failed: 2

Do a test using 0x01FC1F1D.

Scan tests: 4, skipped: 0, failed: 3

Do a test using 0x5533CCAA.

Scan tests: 5, skipped: 0, failed: 4

Do a test using 0xAACC3355.

Scan tests: 6, skipped: 0, failed: 5

Some of the values were corrupted - 83.3 percent.

The JTAG IR Integrity scan-test has failed.

-----[Perform the Integrity scan-test on the JTAG DR]------------------------

This test will use blocks of 512 32-bit words.

This test will be applied just once.

Do a test using 0xFFFFFFFF.

Scan tests: 1, skipped: 0, failed: 0

Do a test using 0x00000000.

Test 2 Word 0: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 1: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 2: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 3: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 4: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 5: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 6: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

Test 2 Word 7: scanned out 0x00000000 and scanned in 0xFFFFFFFF.

The details of the first 8 errors have been provided.

The utility will now report only the count of failed tests.

Scan tests: 2, skipped: 0, failed: 1

Do a test using 0xFE03E0E2.

Scan tests: 3, skipped: 0, failed: 2

Do a test using 0x01FC1F1D.

Scan tests: 4, skipped: 0, failed: 3

Do a test using 0x5533CCAA.

Scan tests: 5, skipped: 0, failed: 4

Do a test using 0xAACC3355.

Scan tests: 6, skipped: 0, failed: 5

Some of the values were corrupted - 83.3 percent.

The JTAG DR Integrity scan-test has failed.

[End: Texas Instruments XDS100v2 USB Emulator_0]