int

main(void)

{

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

uint32_t ui32SysClock;

#endif

//

// This array is used for storing the data read from the ADC FIFO. It

// must be as large as the FIFO for the sequencer in use. This example

// uses sequence 3 which has a FIFO depth of 1. If another sequence

// was used with a deeper FIFO, then the array size must be changed.

//

uint32_t pui32ADC0Value[1];

//

// These variables are used to store the temperature conversions for

// Celsius and Fahrenheit.

//

uint32_t ui32TempValueC;

uint32_t ui32TempValueF;

//

// Set the clocking to run at 20 MHz (200 MHz / 10) using the PLL. When

// using the ADC, you must either use the PLL or supply a 16 MHz clock

// source.

// TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

// crystal on your board.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

ui32SysClock = SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_PLL |

SYSCTL_CFG_VCO_480), 20000000);

#else

SysCtlClockSet(SYSCTL_SYSDIV_10 | SYSCTL_USE_PLL | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

#endif

//

// Set up the serial console to use for displaying messages. This is just

// for this example program and is not needed for ADC operation.

//

configureUART();

//

// Display the setup on the console.

//

UARTprintf("ADC ->\n");

UARTprintf(" Type: Internal Temperature Sensor\n");

UARTprintf(" Samples: One\n");

UARTprintf(" Update Rate: 250ms\n");

UARTprintf(" Input Pin: Internal temperature sensor\n\n");

//

// The ADC0 peripheral must be enabled for use.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0);

//

// Enable sample sequence 3 with a processor signal trigger. Sequence 3

// will do a single sample when the processor sends a singal to start the

// conversion. Each ADC module has 4 programmable sequences, sequence 0

// to sequence 3. This example is arbitrarily using sequence 3.

//

ADCSequenceConfigure(ADC0_BASE, 3, ADC_TRIGGER_PROCESSOR, 0);

//

// Configure step 0 on sequence 3. Sample the temperature sensor

// (ADC_CTL_TS) and configure the interrupt flag (ADC_CTL_IE) to be set

// when the sample is done. Tell the ADC logic that this is the last

// conversion on sequence 3 (ADC_CTL_END). Sequence 3 has only one

// programmable step. Sequence 1 and 2 have 4 steps, and sequence 0 has

// 8 programmable steps. Since we are only doing a single conversion using

// sequence 3 we will only configure step 0. For more information on the

// ADC sequences and steps, reference the datasheet.

//

ADCSequenceStepConfigure(ADC0_BASE, 3, 0, ADC_CTL_TS | ADC_CTL_IE |

ADC_CTL_END);

//

// Since sample sequence 3 is now configured, it must be enabled.

//

ADCSequenceEnable(ADC0_BASE, 3);

//

// Clear the interrupt status flag. This is done to make sure the

// interrupt flag is cleared before we sample.

//

ADCIntClear(ADC0_BASE, 3);

//

// Sample the temperature sensor forever. Display the value on the

// console.

//

while(1)

{

//

// Trigger the ADC conversion.

//

ADCProcessorTrigger(ADC0_BASE, 3);

//

// Wait for conversion to be completed.

//

while(!ADCIntStatus(ADC0_BASE, 3, false))

{

}

//

// Clear the ADC interrupt flag.

//

ADCIntClear(ADC0_BASE, 3);

//

// Read ADC Value.

//

ADCSequenceDataGet(ADC0_BASE, 3, pui32ADC0Value);

//

// Use non-calibrated conversion provided in the data sheet. Make

// sure you divide last to avoid dropout.

//

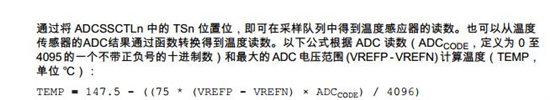

ui32TempValueC = ((1475 * 1023) - (2250 * pui32ADC0Value[0])) / 10230;

//

// Get Fahrenheit value. Make sure you divide last to avoid dropout.

//

ui32TempValueF = ((ui32TempValueC * 9) + 160) / 5;

//

// Display the temperature value on the console.

//

UARTprintf("Temperature = %3d*C or %3d*F\r", ui32TempValueC,

ui32TempValueF);

//

// This function provides a means of generating a constant length

// delay. The function delay (in cycles) = 3 * parameter. Delay

// 250ms arbitrarily.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

SysCtlDelay(ui32SysClock / 12);

#else

SysCtlDelay(SysCtlClockGet() / 12);

#endif

}

}

这是固件库里面的adc温度传感器的一段代码,里面的黄色部分是什么意思,这是如何与板子里面的传感器建立联系的,如果要外接该如何去定义,我没学过c++,

只学过VB,好烦

谢谢