Other Parts Discussed in Thread: DRV8329, CSD19506KTT, UCC27284, , C2000WARE

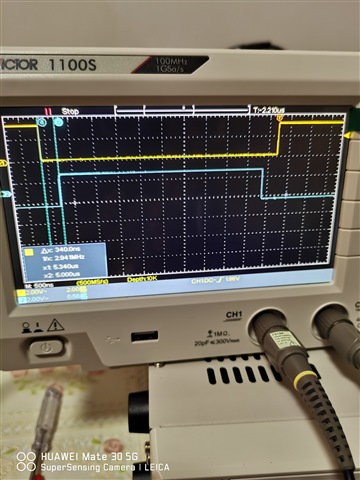

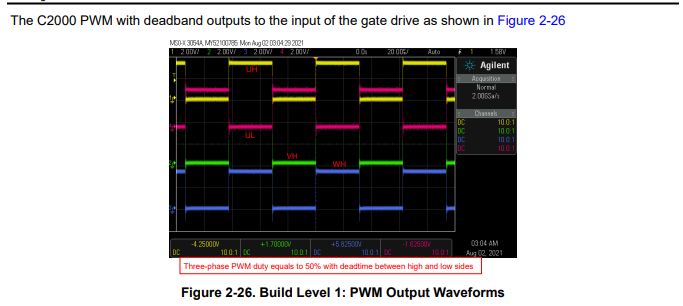

半桥栅极驱动器用3个UCC27284替换DRV8329+CSD19506KTT控制BLDC,问题如下:

1、在hal.c中配置PWM, 实测EPWM3无波形,其他两相有PWM波

// GPIO227->EPWM3A->M1_UH

GPIO_setPinConfig(GPIO_227_EPWM3_A);

GPIO_setDirectionMode(227, GPIO_DIR_MODE_OUT);

GPIO_setPadConfig(227, GPIO_PIN_TYPE_STD);

// GPIO230->EPWM3B->M1_UL

GPIO_setPinConfig(GPIO_230_EPWM3_B);

GPIO_setDirectionMode(230, GPIO_DIR_MODE_OUT);

GPIO_setPadConfig(230, GPIO_PIN_TYPE_STD);

// GPIO0->EPWM1A->M1_VH

GPIO_setPinConfig(GPIO_0_EPWM1_A);

GPIO_setDirectionMode(0, GPIO_DIR_MODE_OUT);

GPIO_setPadConfig(0, GPIO_PIN_TYPE_STD);

// GPIO1->EPWM1B->M1_VL

GPIO_setPinConfig(GPIO_1_EPWM1_B);

GPIO_setDirectionMode(1, GPIO_DIR_MODE_OUT);

GPIO_setPadConfig(1, GPIO_PIN_TYPE_STD);

// GPIO2->EPWM2_A->M1_WH

GPIO_setPinConfig(GPIO_2_EPWM2_A);

GPIO_setDirectionMode(2, GPIO_DIR_MODE_OUT);

GPIO_setPadConfig(2, GPIO_PIN_TYPE_STD);

// GPIO3->EPWM2_B->M1_WL

GPIO_setPinConfig(GPIO_3_EPWM2_B);

GPIO_setDirectionMode(3, GPIO_DIR_MODE_OUT);

GPIO_setPadConfig(3, GPIO_PIN_TYPE_STD);

2、参照DRV8329AEVM控制流程,换成非SPI接口的UCC27284,软件怎么移植,能否提供参考文档?

谢谢