Hello esteemed technical team!

I use MCT8329A designed high power circuit board, I tried to debug it by myself for 60 working hours, and I always fail to reach the normal operation.

My brushless motor has a rated power of 1KW, a maximum design speed of 1500RPM, and an internal resistance of 0.09 ohm in any two of the three wires of the motor coil. The motor is powered by a lithium battery with a maximum voltage of 50V.

My current situation is that no matter how much duty cycle command is given to the motor, the motor can only rotate for 1 second and then stop. It's about 10 revolutions or so.

E2H faults are as follows: LOSS_OF_SYNC=1H,MTR_LCK=1H.

E0H has no faults.

I made the following adjustments to the default registers:

1.MTR_STARTUP=2H.

2.CSA_GAIN=3H.

3.VREF_SEL=0H.

4.CLOSED_LOOP_MODE=1H.

5.MAX SPEED=400HZ.

6.OL_DUTY=6H.

7.OL_ILIMIT=CH.

1.I don't know how to continue modifying the registers, the out of sync fault will keep on occurring, please help me to find out what the problem is?

2. hypothetically what happens if the batteries are not able to charge at the rate required to maintain the closed loop?

Since I did not purchase EVM, please forgive me for not being able to provide the configuration file in file form.

0x80,0x04,0x4D,0x40,0x7F;

0x84,0x95,0X32,0x2D,0x66;

0X8E,0x01,0X00,0x01,0x30;

0x90,0x40,0x06,0xC8,0x00;

0xAC,0xFF,0x00,0x02,0x00;

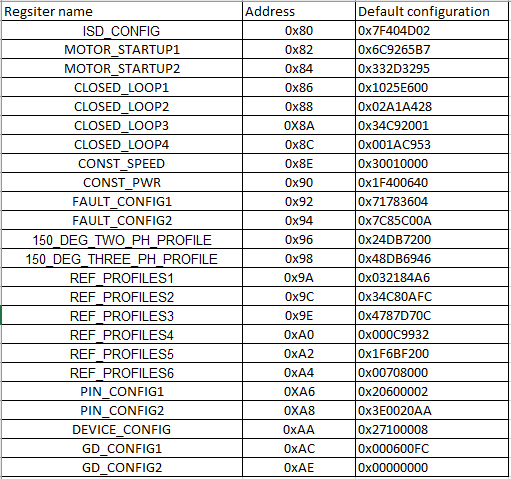

Here is the default register configuration I found.