Other Parts Discussed in Thread: DLP5531-Q1, LM5175

以TI的 DLP5531-Q1的公版驱动电路为基础

更换光源进行驱动,需修改驱动参数

第一种为7.4V LED开关峰值电流16A

第二种为7.0V LED开关峰值电流12A

请问原设计应该修改哪些器件参数

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

以TI的 DLP5531-Q1的公版驱动电路为基础

更换光源进行驱动,需修改驱动参数

第一种为7.4V LED开关峰值电流16A

第二种为7.0V LED开关峰值电流12A

请问原设计应该修改哪些器件参数

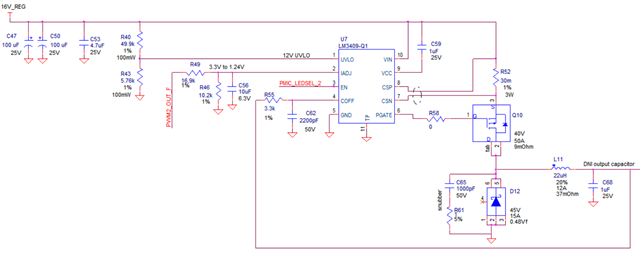

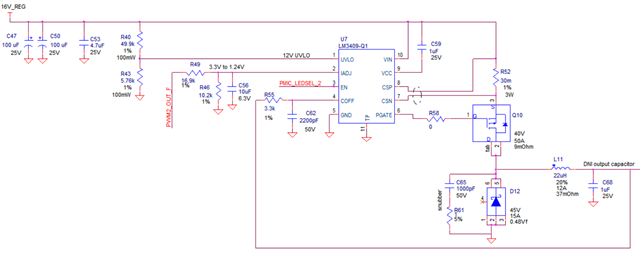

I don't know what you mean by the DLP5531-Q1 public drive circuit? Is this an EVM, app note, or reference design? I need to know the original design before I can recommend how to change it. Can you verify this is the schematic you are referencing?

2515624C_DLP5531-Q1_HL_Driver_Rev-C.pdf

If you want to support 16A @ 7.4V or 12A at 7V you are going to need change FETs, Diodes, and inductors. That is a lot of current and the losses are going to be really big. Heat sinking will be critical. You may want to consider a multiphase approach.

This seems like an uncommon application. Is this for an automotive application? Can you tell me what the load is for this LED driver?

The schematic shows a PWM signal, do you have PWM frequency? duty cycle? linearity requirements? etc???

2515624C_DLP5531-Q1_HL_Driver_Rev-C.pdf

yes, i use this schematic。

this Is for an automotive application

R duty cycle: 30%-35%

G duty cycle :45%-49%

B duty cycle: 20%-30%

LED for Blue&Green

Absolute Maximum Forward Current (Pulsed)

(Frequency > 240Hz, duty cycle < 70%)

I(f max Pulsed)=16A

Test Peak Drive Current

I(f)=10A

Forward Voltage

V(f)=7.4V ;V(fmax)=8V(Blue) ;V(fmax)=7.8V(Green)

LED for Red

Absolute Maximum Forward Current (Pulsed)

(Frequency > 240Hz, duty cycle < 70%)

I(f max Pulsed)=11A

Test Peak Drive Current

I(f)=10A

Forward Voltage

V(f)=6.7V ;V(fmax)=7.6V

How should I adjust these components?(FETs, Diodes, and inductors)

Can you introduce another widely used solution that can be adapted to the circuit diagram of the DLP5531-Q1 and can be adapted to my LED?

I can't say there is anything I know of that is "widely" used. This is not a common use case in automotive LED lighting. If you have the LDP5531EVM then I would probably modify it to see if you can achieve the desired output power. When I looked at the schematic and BOM I noticed they are using 15A diode, that will very likely have to be increased to probably something like a 30A diode and you might potentially be able to put two in parallel, but ensuring equal current between the to diodes will be a challenge, but maybe if the lower losses are low enough it might be ok. This isn't a trivial design change. You are literally doubling the output current and doubling the output voltage. Thus 4x output power when compared to the EVM. You will also have to take into account that the LM5175 (buck-boost) controller will also have to be adjusted to be able to support that output power. I would recommend when doing PWM dimming that you have the channels be out of phase with each other to minimize inrush currents form the drivers. That will help the buck-boost not see such large transients on their output. You're other options to even remotely be able to achieve these output power levels is to do multi-phase outputs. What I mean by that is to have two or three controllers per LED. That will distribute the power losses. Each controller is a constant current source so just connecting the outputs together will generate the total output current needed.

I recommend you go through the datasheet for each device and follow the application section for the design. You will need to change almost every major power component in the design (inductors, FETs, Diode, sense resistor, input and output capacitors).

Who is the customer, what is the end application, what is the start of production, and what are the volumes?

Long time no reply received, this post is closed