Part Number: DP83TD510E

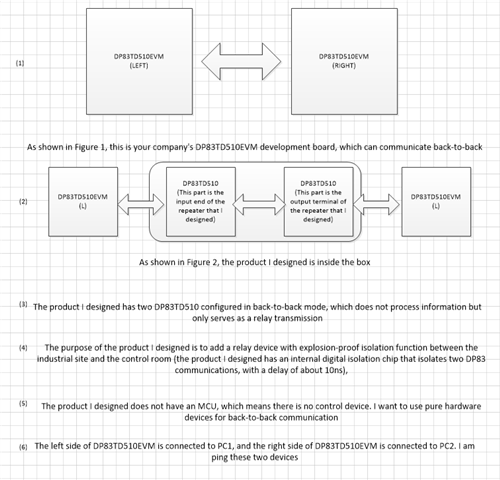

Hello, I would like to inquire about a question regarding DP83TD510E. I am currently designing a repeater that does not require an MCU and uses pure hardware. I aim to achieve back-to-back connection. The conceptual diagram is as follows: Ethernet → DP83TD510EVM → DP83TD510E → DP83TD510E → DP83TD510EVM → Ethernet

The product I designed is placed in the middle of DP83TD510EVM, serving as an isolation repeater. Current tests have revealed that there is a waveform in the circuit, but PING is unsuccessful. I hope you can help me with this issue. I have attached the schematic diagram, could you please take a look and let me know if there are any issues with the design. Thank you.PHD-APL-DEMO.pdf