尊敬的 TI 成员:

我将为 PID 附加一个仿真代码。 我需要您的帮助来解释部分代码:

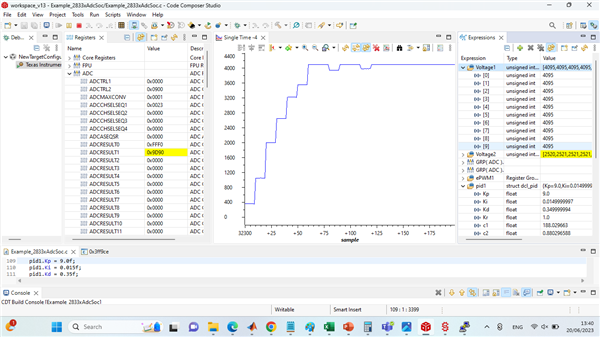

首先:如果 rk =0.25被置位、那么在12位 ADC 值(0-4095)的帮助下以及在代码行342下获得了 YK:

YK=(((float) AdcRegs.ADCRESULT0 - 2048.0f)/ 2047.0f;

Kr 可以介于1和-1之间。 如果(悬空) AdcRegs.ADCRESULT0 介于(4095和0)之间。

现在,下一行345 : Uk = DCL_runPID_C4(&pid1, rk, YS, lk);…… 用于运行 PID 函数。 它提供控制努力值 u (k)。

提问1:问题是 u (k)数值范围的数值是多少???? 请解释第345行。

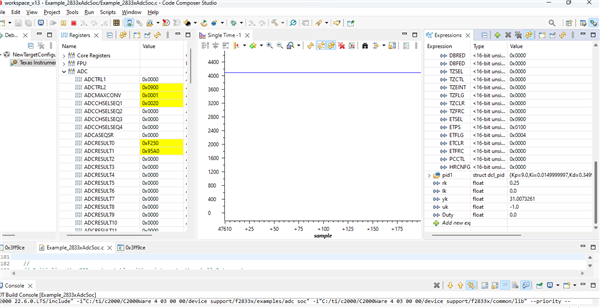

第348行: clampactive = DCL_runClamp_C1 (&uk、upperlim、lowlim);定义上限和下限饱和。

问题2:第350行: LK =(clampactive == 0U)? 1.0f: 0.0f;.. 没有强制选择1或0为 Clampactive。 我们可以选择其中任何一个吗???

对于353-354行:

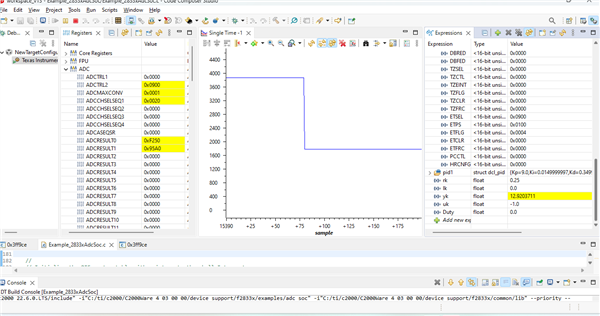

Duty =(UK / 2.0f + 0.5f)*(float) EPwm1Regs.TBPRD;

EPwm1Regs.CMPA.half.CMPA =(UINT16)占空比;

问题3:

F ROM 上面的行、如果已知问题1中的 u (k)、那么为什么要除以2.5 (2.0f+0.5f)、然后乘以 EPwm1Regs.TBPRD? 这个 ePWM 是我们在第286行(EPwm1Regs.TBPRD = 0xFFFF)对 ADC 采样的 ePWM。 如果是、那么如果假设您的 y (k)将会费更改为 ADC 值、上述占空比会如何变化? 我想我应该删除线路309、然后检查 GPIO0或者 GPIO1、如果 y (k)发生变化、那么占空比会发生变化。

//########################################################################### // // FILE: Example_2833xAdcSoc.c // // TITLE: ADC Start of Conversion Example // //! \addtogroup f2833x_example_list //! <h1> ADC Start of Conversion (adc_soc)</h1> //! //! This ADC example uses ePWM1 to generate a periodic ADC SOC on SEQ1. //! Two channels are converted, ADCINA3 and ADCINA2. //! //! \b Watch \b Variables \n //! - Voltage1[10] - Last 10 ADCRESULT0 values //! - Voltage2[10] - Last 10 ADCRESULT1 values //! - ConversionCount - Current result number 0-9 //! - LoopCount - Idle loop counter // //########################################################################### // $TI Release: $ // $Release Date: $ // $Copyright: // Copyright (C) 2009-2023 Texas Instruments Incorporated - http://www.ti.com/ // // Redistribution and use in source and binary forms, with or without // modification, are permitted provided that the following conditions // are met: // // Redistributions of source code must retain the above copyright // notice, this list of conditions and the following disclaimer. // // Redistributions in binary form must reproduce the above copyright // notice, this list of conditions and the following disclaimer in the // documentation and/or other materials provided with the // distribution. // // Neither the name of Texas Instruments Incorporated nor the names of // its contributors may be used to endorse or promote products derived // from this software without specific prior written permission. // // THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS // "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT // LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR // A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT // OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, // SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT // LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, // DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY // THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT // (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE // OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. // $ //########################################################################### // // Included Files // #include "DSP28x_Project.h" // Device Headerfile and Examples Include File #include "DSP2833x_Device.h" #include "DSP2833x_Examples.h" #include "DSP2833x_GlobalPrototypes.h" #include "DCLF32.h" // // Function Prototypes // void gpio_select(void); void Setup_ePWM1(void); __interrupt void adc_isr(void); // // Globals // Uint16 LoopCount; Uint16 ConversionCount; Uint16 Voltage1[10]; Uint16 Voltage2[10]; //DCL_PID pid1 = PID_DEFAULTS; //typedef struct dcl_pid pid1; struct dcl_pid pid1; //float pid1; DCL_PID pid1 = PID_DEFAULTS; float32_t yk; float32_t lk; float32_t uk; //float32_t rk = 0.25; // initial value for control reference //float32_t lk = 1.0; // control loop not saturated float32_t rk; // initial value for control reference float32_t lk; // control loop not saturated float Duty; float upperlim = 0.95; float lowerlim = 0.05; unsigned int clampactive; // // Main // void main(void) { //DCL_PID pid1 = PID_DEFAULTS; pid1.Kp = 9.0f; pid1.Ki = 0.015f; pid1.Kd = 0.35f; pid1.Kr = 1.0f; pid1.c1 = 188.0296600613396f; pid1.c2 = 0.880296600613396f; pid1.d2 = 0.0f; pid1.d3 = 0.0f; pid1.i10 = 0.0f; pid1.i14 = 1.0f; pid1.Umax = 1.0f; pid1.Umin = -1.0f; rk = 0.25; // initial value for control reference lk = 1.0; // // Step 1. Initialize System Control: // PLL, WatchDog, enable Peripheral Clocks // This example function is found in the DSP2833x_SysCtrl.c file. // InitSysCtrl(); EALLOW; #if (CPU_FRQ_150MHZ) // Default - 150 MHz SYSCLKOUT // // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 150/(2*3) = 25.0 MHz // #define ADC_MODCLK 0x3 #endif #if (CPU_FRQ_100MHZ) // // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 100/(2*2) = 25.0 MHz // #define ADC_MODCLK 0x2 #endif EDIS; // // Define ADCCLK clock frequency ( less than or equal to 25 MHz ) // Assuming InitSysCtrl() has set SYSCLKOUT to 150 MHz // EALLOW; SysCtrlRegs.HISPCP.all = ADC_MODCLK; EDIS; // // Step 2. Initialize GPIO: // This example function is found in the DSP2833x_Gpio.c file and // illustrates how to set the GPIO to it's default state. // // InitGpio(); // Skipped for this example // // Step 3. Clear all interrupts and initialize PIE vector table: // Disable CPU interrupts // DINT; // // Initialize the PIE control registers to their default state. // The default state is all PIE interrupts disabled and flags // are cleared. // This function is found in the DSP2833x_PieCtrl.c file. // InitPieCtrl(); // // Disable CPU interrupts and clear all CPU interrupt flags: // IER = 0x0000; IFR = 0x0000; // // Initialize the PIE vector table with pointers to the shell Interrupt // Service Routines (ISR). // This will populate the entire table, even if the interrupt // is not used in this example. This is useful for debug purposes. // The shell ISR routines are found in DSP2833x_DefaultIsr.c. // This function is found in DSP2833x_PieVect.c. // InitPieVectTable(); // // Interrupts that are used in this example are re-mapped to // ISR functions found within this file. // EALLOW; // This is needed to write to EALLOW protected register PieVectTable.ADCINT = &adc_isr; EDIS; // This is needed to disable write to EALLOW protected registers //* configure ePWM1 */ EALLOW; SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 0; EDIS; //InitEPwm1Gpio(); // [F2806x_EPwm.c] gpio_select(); Setup_ePWM1(); // init ePWM1A //void Setup_ePWM1(void) //{ //EPwm1Regs.TBCTL.bit.CTRMODE = 3; // freeze TB counter //EPwm1Regs.TBCTL.bit.PRDLD = 1; // immediate load //EPwm1Regs.TBCTL.bit.PHSEN = 0; // disable phase loading //EPwm1Regs.TBCTL.bit.SYNCOSEL = 3; // disable SYNCOUT signal //EPwm1Regs.TBCTL.bit.HSPCLKDIV = 0; // TBCLK = SYSCLKOUT //EPwm1Regs.TBCTL.bit.CLKDIV = 0; // clock divider = /1 //EPwm1Regs.TBCTL.bit.FREE_SOFT = 2; // free run on emulation suspend //EPwm1Regs.TBPRD = 0x2328; // set period for ePWM1 (0x2328 = 10kHz) //EPwm1Regs.TBPHS.all = 0; // time-base Phase Register //EPwm1Regs.TBCTR = 0; // time-base Counter Register //EPwm1Regs.ETSEL.bit.SOCAEN = 1; // enable SOC on A group //EPwm1Regs.ETSEL.bit.SOCASEL = 1; // select SOC from zero match //EPwm1Regs.ETPS.bit.SOCAPRD = 1; // generate pulse on 1st event //EPwm1Regs.CMPCTL.bit.SHDWAMODE = 0; // enable shadow mode //EPwm1Regs.CMPCTL.bit.LOADAMODE = 2; // reload on CTR=zero //EPwm1Regs.CMPA.half.CMPA = 0x0080; // set compare A value //EPwm1Regs.AQCTLA.bit.CAU = AQ_SET; // HIGH on CMPA up match //EPwm1Regs.AQCTLA.bit.ZRO = AQ_CLEAR; // LOW on zero match //} EALLOW; SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 1; EDIS; // // Step 4. Initialize all the Device Peripherals: // This function is found in DSP2833x_InitPeripherals.c // // InitPeripherals(); // Not required for this example InitAdc(); // For this example, init the ADC // // Step 5. User specific code, enable interrupts: // //gpio_select(); //Setup_ePWM1(); // init ePWM1A,ePWM1B // // Enable ADCINT in PIE // PieCtrlRegs.PIEIER1.bit.INTx6 = 1; IER |= M_INT1; // Enable CPU Interrupt 1 EINT; // Enable Global interrupt INTM ERTM; // Enable Global realtime interrupt DBGM LoopCount = 0; ConversionCount = 0; // // Configure ADC // AdcRegs.ADCMAXCONV.all = 0x0001; // Setup 2 conv's on SEQ1 AdcRegs.ADCCHSELSEQ1.bit.CONV00 = 0x3; // Setup ADCINA3 as 1st SEQ1 conv. AdcRegs.ADCCHSELSEQ1.bit.CONV01 = 0x2; // Setup ADCINA2 as 2nd SEQ1 conv. // // Enable SOCA from ePWM to start SEQ1 // AdcRegs.ADCTRL2.bit.EPWM_SOCA_SEQ1 = 1; AdcRegs.ADCTRL2.bit.INT_ENA_SEQ1 = 1; // Enable SEQ1 interrupt (every EOS) // // Assumes ePWM1 clock is already enabled in InitSysCtrl(); // EPwm1Regs.ETSEL.bit.SOCAEN = 1; // Enable SOC on A group EPwm1Regs.ETSEL.bit.SOCASEL = 4; // Select SOC from from CPMA on upcount EPwm1Regs.ETPS.bit.SOCAPRD = 1; // Generate pulse on 1st event EPwm1Regs.CMPA.half.CMPA = 0x0080; // Set compare A value EPwm1Regs.TBPRD = 0xFFFF; // Set period for ePWM1 EPwm1Regs.TBCTL.bit.CTRMODE = 0; // count up and start // // Wait for ADC interrupt // for(;;) { LoopCount++; } } // void Setup_ePWM1(void) { EPwm1Regs.TBCTL.bit.CTRMODE = 3; // freeze TB counter EPwm1Regs.TBCTL.bit.PRDLD = 1; // immediate load EPwm1Regs.TBCTL.bit.PHSEN = 0; // disable phase loading EPwm1Regs.TBCTL.bit.SYNCOSEL = 3; // disable SYNCOUT signal EPwm1Regs.TBCTL.bit.HSPCLKDIV = 0; // TBCLK = SYSCLKOUT EPwm1Regs.TBCTL.bit.CLKDIV = 0; // clock divider = /1 EPwm1Regs.TBCTL.bit.FREE_SOFT = 2; // free run on emulation suspend EPwm1Regs.TBPRD = 0x2328; // set period for ePWM1 (0x2328 = 10kHz) EPwm1Regs.TBPHS.all = 0; // time-base Phase Register EPwm1Regs.TBCTR = 0; // time-base Counter Register EPwm1Regs.ETSEL.bit.SOCAEN = 1; // enable SOC on A group EPwm1Regs.ETSEL.bit.SOCASEL = 1; // select SOC from zero match EPwm1Regs.ETPS.bit.SOCAPRD = 1; // generate pulse on 1st event EPwm1Regs.CMPCTL.bit.SHDWAMODE = 0; // enable shadow mode EPwm1Regs.CMPCTL.bit.LOADAMODE = 2; // reload on CTR=zero EPwm1Regs.CMPA.half.CMPA = 0x0080; // set compare A value EPwm1Regs.AQCTLA.bit.CAU = AQ_SET; // HIGH on CMPA up match EPwm1Regs.AQCTLA.bit.ZRO = AQ_CLEAR; // LOW on zero match } void gpio_select(void) { EALLOW; GpioCtrlRegs.GPAPUD.bit.GPIO0 = 0; // Enable pullup on GPIO0 GpioCtrlRegs.GPAPUD.bit.GPIO1 = 0; // Enable pullup on GPIO1 GpioCtrlRegs.GPAMUX1.bit.GPIO0 = 1; // GPIO0 = PWM1A GpioCtrlRegs.GPAMUX1.bit.GPIO1 = 1; // GPIO0 = PWM1B EDIS; } // adc_isr - // __interrupt void adc_isr(void) { Voltage1[ConversionCount] = AdcRegs.ADCRESULT0 >>4; Voltage2[ConversionCount] = AdcRegs.ADCRESULT1 >>4; // read ADC channel yk = ((float) AdcRegs.ADCRESULT0 - 2048.0f) / 2047.0f; // run PID controller uk = DCL_runPID_C4(&pid1, rk, yk, lk); // external clamp for anti-windup reset clampactive = DCL_runClamp_C1(&uk, upperlim, lowerlim); //clampactive = DCL_runClamp_C1(&uk, Umax, Umin); lk = (clampactive == 0U) ? 1.0f : 0.0f; // write u(k) to PWM Duty = (uk / 2.0f + 0.5f) * (float) EPwm1Regs.TBPRD; EPwm1Regs.CMPA.half.CMPA = (Uint16) Duty; // // If 40 conversions have been logged, start over // if(ConversionCount == 9) { ConversionCount = 0; } else { ConversionCount++; } // // Reinitialize for next ADC sequence // AdcRegs.ADCTRL2.bit.RST_SEQ1 = 1; // Reset SEQ1 AdcRegs.ADCST.bit.INT_SEQ1_CLR = 1; // Clear INT SEQ1 bit PieCtrlRegs.PIEACK.all = PIEACK_GROUP1; // Acknowledge interrupt to PIE return; } // // End of File //

请分步解释所有问题。 抱歉、我不熟悉 DCL PID 仿真。

谢谢

此致

阿尔萨兰