Part Number: TIDM-02013

Other Parts Discussed in Thread: PMP22650

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Part Number: TIDM-02013

Other Parts Discussed in Thread: PMP22650

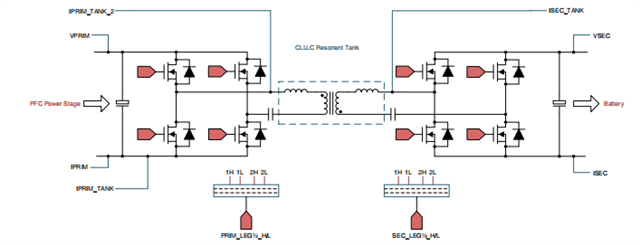

I tried swapping the current input and output terminals of the Hall sensor, yet this did not resolve the short-circuit issue in the secondary-side circuit. I then measured the gate drives of the primary-side 2L bridge and secondary-side 2L bridge, and observed that the two drive signals—which should have been in phase—now had a phase difference of 180°. This is likely the root cause of the short circuit. The problem should lie in an incorrect reference of the drive signals for the secondary-side bridge arm, but I have no idea where to modify the settings.I recall that the code describes the secondary-side drive being referenced to the primary side, yet I cannot locate the function where this reference is configured. Could you please advise me on this?

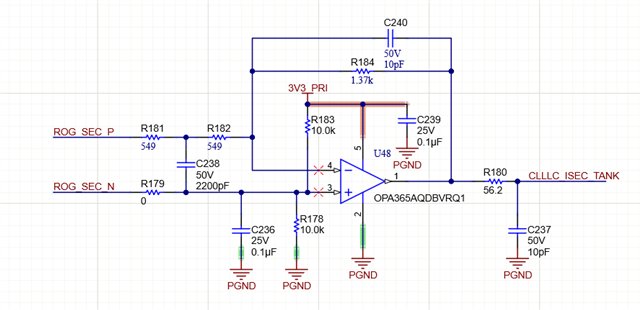

The blue line represents the sampled current after the operational amplifier, the purple line represents the driving waveform of the primary-side 2L after the isolation chip, and the yellow line represents the driving waveform of the secondary-side 2L before the isolation chip.

I apologize for troubling you so frequently. This experiment is of great importance to me, and I truly appreciate you taking the time to answer my questions.

For 02013, the transformer polarity is positive, so the macro CLLLC_TRANSFORMER_POLARITY should be set to CLLLC_POSITIVE_POLARITY.

#if CLLLC_TRANSFORMER_POLARITY == CLLLC_POSITIVE_POLARITY

//The following code should be used when the transformer polarity matches the schematic.

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_U, EPWM_TZ_ADV_ACTION_LOW);

#else

//The following code should be used when the transformer polarity does not match the schematic.

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG1_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZA_D, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_U, EPWM_TZ_ADV_ACTION_LOW);

EPWM_setTripZoneAdvAction(CLLLC_SEC_LEG2_PWM_BASE, EPWM_TZ_ADV_ACTION_EVENT_TZB_D, EPWM_TZ_ADV_ACTION_LOW);

#endif

In clllc_user_setting.h

#define CLLLC_TRANSFORMER_POLARITY CLLLC_NEGATIVE_POLARITY

Hi,

May I know what HW is used here. Is it PMP22650 or any change to that?