主题中讨论的其他器件:UCC21710、 C2000WARE、 SysConfig

您好!

我们想使用来自 UCC21710生成的 PWM 脉冲序列的 eCAP 模块测量直流总线。我们需要对 eCAP 模块进行一些澄清。

首先、eCAP 能否测量400kHz PWM 脉冲序列的占空比?我问这个问题、因为查看 c2000ware 中的示例项目、我发现它正在测量几 kHz 的 PWM 脉冲序列。

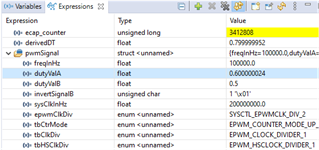

我们尝试模拟同一个示例,但在较高的频率下,但随着我们增加 PWM 频率,占空比计算不断恶化。 变量 衍生 DT 是根据 eCAP 模块计算得出的结果。

__interrupt void INT_myECAP0_ISR(void)

{

ecap_counter++;

cap1_count = ECAP_getEventTimeStamp(myECAP0_BASE, ECAP_EVENT_1); //1st raising edge

cap2_count = ECAP_getEventTimeStamp(myECAP0_BASE, ECAP_EVENT_2); //1st falling edge

cap3_count = ECAP_getEventTimeStamp(myECAP0_BASE, ECAP_EVENT_3); //2nd raising edge

cap4_count = ECAP_getEventTimeStamp(myECAP0_BASE, ECAP_EVENT_4); //2nd falling edge

derivedDT = (float)(cap2_count-cap1_count)/(cap3_count-cap1_count);

ECAP_reArm(myECAP0_BASE);

ECAP_clearGlobalInterrupt(myECAP0_BASE);

ECAP_clearInterrupt(myECAP0_BASE, ECAP_ISR_SOURCE_CAPTURE_EVENT_4);

Interrupt_clearACKGroup(INTERRUPT_ACK_GROUP4);

}

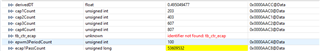

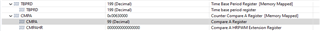

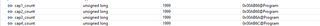

在10kHz 时:

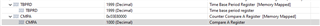

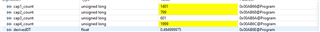

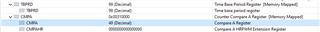

100kHz 时的频率

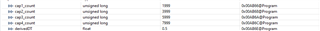

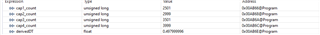

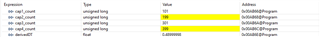

500kHz 时: