工具与软件:

您好!

我将尝试实施 ADC 比较器中断、以便在测量的电压高于0.11V 时红色 LED 亮起、并在低于0.11V (约为136/4096 * 3.3V)时熄灭。 下面是我的代码。 我怀疑 InitADC 和 ADC0Seq2Handler 中的中断条件/配置有问题。 我已经正确地更新了 startup_ccs.c 中的矢量表

#define ADC_SEQUENCER3_LENGTH 1

#define ADC_SEQUENCER2_LENGTH 4

#define ADC_SEQUENCER1_LENGTH 4

#define ADC_SEQUENCER0_LENGTH 8

#define VOLTAGE_PRIORITY 0

#define VOLTAGE_CALIBRATION_FACTOR 1.008

uint32_t VoltBuf[ADC_SEQUENCER2_LENGTH]; // SS2 has the size of 4 samples

uint32_t voltage;

int32_t VoltIntegerPart;

int32_t VoltFractionPart;

void ADC0Seq2Handler(void){

IntMasterDisable();

uint32_t ulStatus = ADCIntStatus(ADC0_BASE, 2, true);

uint32_t comparatorStatus = ADCComparatorIntStatus(ADC0_BASE);

ADCIntClear(ADC0_BASE,2);

if (comparatorStatus & (1 << 0)) {

GPIOPinWrite(GPIO_PORTF_BASE, GPIO_PIN_2, GPIO_PIN_2);

ADCComparatorIntClear(ADC0_BASE, 0);

}

if (comparatorStatus & (1 << 1)) {

GPIOPinWrite(GPIO_PORTF_BASE, GPIO_PIN_2, 0);

ADCComparatorIntClear(ADC0_BASE, 1);

}

IntMasterEnable();

}

void InitADC(void){

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE);

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_3); // Configure PE3 as an ADC input

SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0); // Enable the ADC0 peripheral

ADCHardwareOversampleConfigure(ADC0_BASE,32); // Set the auto average to 64

// Configure sequence 2 for voltage measurement on AIN0 (PE)

ADCSequenceDisable(ADC0_BASE, 2); // Disable sequence 2

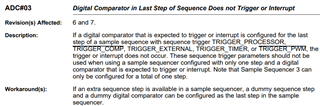

ADCSequenceConfigure(ADC0_BASE, 2, ADC_TRIGGER_PROCESSOR, VOLTAGE_PRIORITY); // Configure sequence 2

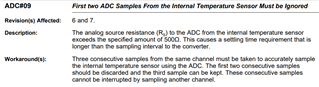

ADCSequenceStepConfigure(ADC0_BASE, 2, 0, ADC_CTL_CH0);

ADCSequenceStepConfigure(ADC0_BASE, 2, 1, ADC_CTL_CH0);

ADCSequenceStepConfigure(ADC0_BASE, 2, 2, ADC_CTL_CH0);

ADCSequenceStepConfigure(ADC0_BASE, 2, 3, ADC_CTL_CH0 | ADC_CTL_IE | ADC_CTL_END); // Set up the last step and start an interrupt when the conversion is over

ADCSequenceEnable(ADC0_BASE, 2); // Enable the sequence again

ADCIntEnable(ADC0_BASE,0);

ADCIntClear(ADC0_BASE, 2); // Clear the interrupt flag

// Configure the ADC comparator

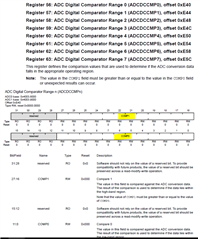

ADCComparatorConfigure(ADC0_BASE, 1, ADC_COMP_TRIG_NONE | ADC_COMP_INT_HIGH_HALWAYS); ////////////////////////////////////////////////////////////////////////////////// could be wrong

ADCComparatorRegionSet(ADC0_BASE, 0, 136, 4095); // Set the comparator region (136 corresponds to 0.11V)

ADCComparatorReset(ADC0_BASE, 0, true, true); // Reset the comparator

ADCComparatorIntEnable(ADC0_BASE, 0); // Enable the comparator interrupt

ADCComparatorConfigure(ADC0_BASE, 2, ADC_COMP_TRIG_NONE | ADC_COMP_INT_LOW_HALWAYS ); ////////////////////////////////////////////////////////////////////////////////// could be wrong

ADCComparatorRegionSet(ADC0_BASE, 1, 0, 136); // Set the comparator region (136 corresponds to 0.11V)

ADCComparatorReset(ADC0_BASE, 1, true, true); // Reset the comparator

ADCComparatorIntEnable(ADC0_BASE, 1); // Enable the comparator interrupt

IntEnable(INT_ADC0SS2); // Enable the ADC sequence 2 interrupt in the NVIC

IntMasterEnable();

}

void InitGPIO(void) {

// Enable the GPIO port for the LED (PF2)

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOF);

GPIOPinTypeGPIOOutput(GPIO_PORTF_BASE, GPIO_PIN_1); // Configure PF2 as an output

GPIOPinWrite(GPIO_PORTF_BASE, GPIO_PIN_1, 0); // Initialize the LED to be off

}

void main(void) {

SysCtlClockSet(SYSCTL_SYSDIV_2_5 | SYSCTL_USE_PLL | SYSCTL_OSC_MAIN | SYSCTL_XTAL_16MHZ); // System clock: 16*12.5/2.5 = 80MHz (MAX)

InitADC();

InitGPIO();

while(1){}

}

现在、PE3正在收集电压数据、我已确认它工作正常。 怎么了?